Imagine transforming your business with just small, consistent changes. Welcome to the world of Kaizen—a philosophy that has revolutionized industries worldwide by fostering continuous improvement.

Originating from Japan, Kaizen empowers organizations to enhance productivity, eliminate waste, and boost employee engagement through incremental advancements.

Whether you’re a manager, entrepreneur, or team leader, embracing Kaizen can be the key to unlocking unparalleled success.

Dive into this comprehensive guide to discover how the Kaizen continuous improvement process can reshape your business landscape and drive sustained growth.

Understanding Kaizen Philosophy

Kaizen isn’t a fancy foreign word to sprinkle into conversations. It’s a game-changer for companies itching to boost productivity and get stuff done efficiently. Let’s break down where it comes from and what makes it tick.

Definition and Origin of Kaizen

Kaizen basically means making small, steady changes that help everyone, everywhere. It’s an idea that believes even tiny steps forward are steps in the right direction. This approach was born in Japan after World War II and helped transform the nation into an economic giant.

The word itself fuses “Kai” (change) and “Zen” (good), meaning good change or improvement, and it’s all about those everyday upgrades.

The Toyota Production System, brainchild of Taiichi Ohno, is a poster child for Kaizen in action. The approach hit the global big time thanks to Masaaki Imai’s 1986 book, The Key to Japan’s Competitive Success.

Core Principles of Kaizen

There are five main ideas you’ll find at the heart of Kaizen. Here’s what they’re all about:

- Know Your Customer: Keep your finger on the pulse of what your customers want and make sure you meet their needs without any fuss.

- Process Flow: It’s like keeping a river free from boulders—processes need to stream along easily to pump up productivity.

- Gemba Walks: Get out there and see stuff firsthand with your own eyes. This means walking the factory floor or office to really get what’s going on.

- Empower People: Your employees are treasure troves of ideas. Let them pitch and run with their suggestions for improvements.

- Foster Transparency: Open doors and open minds—keep communication clear to build trust and teamwork across the board.

To get a grip on these ideas and see how they come to life, swing by our page on kaizen principles.

Grasping these basics gives managers and entrepreneurs a leg up in embracing Kaizen. For more training and tips, check our kaizen training and kaizen training programs pages. If you’re curious about making Kaizen work in real-world business, don’t miss the kaizen implementation and kaizen process improvement sections. It’s all there to help you drive that good change forward!

Implementing Kaizen Methodology

Kaizen, a nifty Japanese habit of always getting better, has been making stuff work well for businesses all over. Let’s dig into how companies can get this Kaizen thing going smoothly.

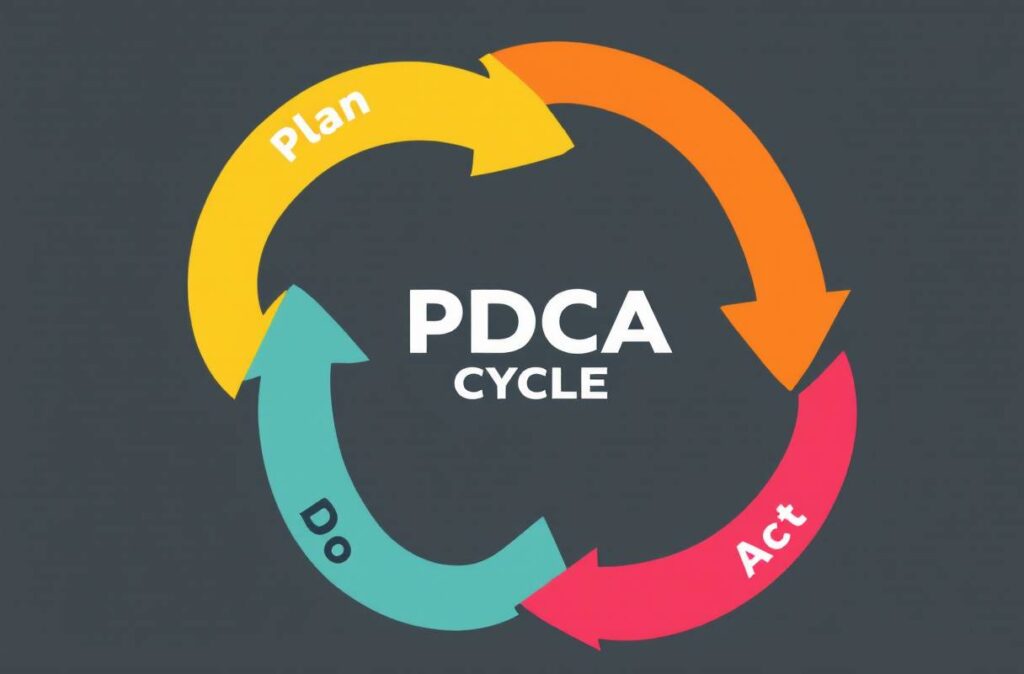

The Kaizen Process Cycle (PDCA)

Ever heard of PDCA? It’s Plan, Do, Check, Act. Think of it as a loop that never stops—like your least favorite song on replay! It’s scientific-like and makes sure improvements keep on rolling.

- Plan: Find something that needs fixing, and come up with a clever plan.

- Do: Try that plan out on a small scale—no “go big or go home” just yet.

- Check: See if the plan was a hit or a miss.

- Act: Make those changes on a bigger scale if it worked. If not, tweak the game plan and start over.

| Kaizen Cycle Step | Description |

|---|---|

| Plan | Cook up a strategy to tackle an issue or spice up a process |

| Do | Roll out the plan with baby steps |

| Check | Check out what’s working and what’s not |

| Act | Go big with successful changes or go back to the drawing board |

PDCA’s like a perfect loop that keeps making things better. To do this the smart way, check our kaizen project page.

Role of Standardized Work

Standardized Work is like the ultimate playbook for doing things right. It’s the solid ground on which Kaizen will build some cool improvements.

- Documentation: Lays out the game plan—steps, sequence, and rhythm of tasks.

- Living Document: Keeps tweaking as you discover better ways during Kaizen throwdowns.

Why bother with standardized work? Well, it helps you to:

- Keep things consistent.

- Spot the mess-ups and the fix-ups.

- Teach the newbies what’s what in double quick time.

Keeping this paperwork sorted out means you can keep ironing out those wrinkles. For a deeper dive, visit our piece on kaizen practices.

Importance of Continuous Improvement Culture

Kaizen isn’t just a bag of tricks; it’s a whole attitude. Having a team-up mentality where everyone’s chipping in is super crucial for Kaizen.

Key bits of a “get better” culture:

- Employee Involvement: People at all layers are all about spotting and sharing better ideas.

- Management Support: Bosses need to be cheerleaders for the Kaizen vibe.

- Regular Training: Keep the crew in the loop with ongoing kaizen training.

- Recognition and Reward: Clap for and cheer those who bring the goods.

Companies that groove on this betterment beat tend to see happier workers and long-term wins. Get your team synced up by browsing our kaizen culture material.

By knowing and doing these Kaizen steps, companies can seriously ramp up in getting things done faster, better, and with a lot more success. For whiz kid tips and tricks, pop over to our kaizen techniques area.

Kaizen in Action

Adopting the kaizen continuous improvement process can really shake things up in an organization for the better. Let’s check out its magic in lean manufacturing, along with the go-to tools and techniques, and see how value stream mapping and Kaizen events fit into the picture.

Application in Lean Manufacturing

Kaizen shines in lean manufacturing by tackling waste head-on — or as the pros call it, Muda. There are seven types of waste that we’re aiming to squash: overproduction, waiting, transport, extra processing, inventory, motion, and defects. By constantly ironing out these wrinkles, lean manufacturing looks to slash costs, nail accuracy, and keep the whole production line humming smoothly.

| Waste Type | Description | Impact on Production |

|---|---|---|

| Overproduction | Churning out more than you need | Jacked-up storage costs |

| Waiting | Sitting around for processes or materials | Production dawdles |

| Transport | Shuffling stuff around needlessly | More handling hustle |

| Extra Processing | Doing more work than what’s needed | Cranked-up energy and labor bills |

| Inventory | Unused products and materials piling up | Your money gets stuck |

| Motion | Pointless moving around by workers | Wears folks out and slows things |

| Defects | Flawed products not up to snuff | Do-overs and waste |

Tools and Techniques in Kaizen

Kaizen has a bag of tricks that keep the ball rolling. These tools help spot and boot inefficiencies out the door. Feast your eyes on some handy kaizen tools and techniques:

- 5 Whys: It’s a game where you ask “why” five times to dig up the root of the problem.

- Kanban: A card game to flag when something needs a fix.

- PDCA Cycle (Plan-Do-Check-Act): A four-step shuffle to change things up and keep them rolling.

- 5S: A tidy-up tactic using these five steps: Sort (Seiri), Set in order (Seiton), Shine (Seiso), Standardize (Seiketsu), and Sustain (Shitsuke).

We’ve got a whole page on kaizen techniques for more info.

Value Stream Mapping and Kaizen Events

Value stream mapping (VSM) is like an x-ray of your process, showing how stuff moves and ideas spread. VSM gets teams from different departments on the same page, helping them spot and fix waste (ClickUp). By looking at the big picture, companies can scrap inefficiencies and pinpoint ways to do things better.

Kaizen events, sometimes called blitzes or rapid-improvement events, are all about zeroing in on specific issues. Running these for three to five days, teams come together to tackle a problem and make change happen fast.

Here’s what happens in a Kaizen event:

- Defining the Scope: Picking a problem or process begging for improvement.

- Current State Analysis: Sketching out the present process using VSM.

- Root Cause Analysis: Digging into the problem with techniques like the 5 Whys.

- Solution Development: Throwing ideas around and sketching out workable fixes.

- Implementation: Making those changes in a well-supervised setting.

- Review and Standardization: Checking how the changes went down and making them routine.

Need more details? Our articles on lean kaizen and kaizen events may just have what you’re after.

Bringing these tools and approaches into your company can boost efficiency, productivity, and quality — the heart of Kaizen’s improvement promise. For more on embedding these tactics, visit Kaizen implementation and Kaizen quality improvement.

Kaizen and Organizational Development

Kaizen for Cultural Change

Forget those big overnight makeovers; Kaizen is here to subtly transform the vibe of a company from the roots up. It’s not only about perking up productivity but also shaking up the organization’s whole mindset.

Born from Toyota’s game-changing playbook, this philosophy is all about cutting down on errors, kicking waste to the curb, and sparking that creative flame among employees while getting everyone on board with the idea that small changes can make a massive difference.

Elements of Kaizen-Driven Cultural Change:

- Employee Empowerment: Employees take the reins in their roles, pitching in fresh ideas for tweaks and changes, which boosts accountability and makes everyone feel like they’re an important piece of the puzzle.

- Collaboration: Teams from different corners come together to crack problems, tearing down any barriers and crafting a unified force.

- Incremental Improvements: It’s about those small, regular tweaks instead of huge leaps, promising a smoother, more sustainable ride.

Challenges and Solutions in Kaizen Implementation

Rolling out Kaizen is no walk in the park. It comes with its own set of hurdles, but identifying and tackling these can open doors to a successful overhaul.

| Challenge | Solution |

|---|---|

| Resistance to Change | Offering ongoing kaizen training and clearly broadcasting the perks can help calm the waters. Sharing stories of success, like Kaizen at Toyota: A Case Study, can be the convincing nudge teams need. |

| Lack of Understanding | Setting up a solid routine for keeping tabs on Kaizen initiatives (Kaizen Techniques) can keep the motivation alive and kicking. |

| Sustaining Efforts | Setting up a solid routine for keeping tabs on Kaizen initiatives (Kaizen Techniques) can keep motivation alive and kicking. |

Strategies for Overcoming Challenges

- Leadership Commitment: Top dogs need to commit big time. Leaders should wave the Kaizen flag proudly and lead the charge.

- Kaizen Workshops and Training: Organize regular kaizen workshops to reinforce the nuts and bolts of Kaizen so that both rookies and veterans keep up with the tune.

- Recognition and Rewards: Give a shoutout to those who push for constant improvement. It not only encourages more of the good stuff but also engrains these habits into the company culture.

- Effective Communication: Foster open channels for folks to toss around ideas and concerns, keeping everything transparent and inclusive.

Kaizen isn’t just an approach; it’s a cornerstone for cultivating a perpetually improving culture and busting through barriers. Want to learn more? Check out our pieces on kaizen principles and kaizen management for more juicy insights into making Kaizen your secret weapon for lasting success.

Benefits of Kaizen

Jumping into the Kaizen way offers a treasure trove of goodies for any organization. This process isn’t just about change—it’s about constantly rocking that boat for a smoother, faster ride. We’re talking boosts in everything from efficiency to staff morale.

Improving Efficiency and Quality

Kaizen is like the secret sauce for running a smooth operation. By sticking with it, you can quietly tackle inefficiency and quality issues through ongoing tweaks and fixes. The trick is about keeping your eyes on the little changes that add up over time, much like ants building an anthill—one tiny bit at a time.

With Kaizen, companies can:

- Cut down on waste

- Get a quality boost with standardized steps

- Slash production time

The folks at Kaizen Institute rolled out some stats showing that Kaizen can beef up efficiency and quality by about 20-30% as you go along. Not too shabby, right?

Increasing Productivity and Employee Engagement

It turns out that Kaizen is a twofer: better productivity and happier workers. When folks get a say in how to do stuff better, they tend to dig in and feel more like part of the family. Plus, getting everyone involved in improvements pumps up teamwork like nobody’s business.

The great stuff includes:

- A morale high that comes from having a voice

- Better teamwork thanks to group efforts in the improvement

- Less downtime because things just run smoother

| Metrics | Improvement (%) |

|---|---|

| Employee Productivity | Up to 25% |

| Employee Morale & Engagement | Up to 30% |

And we aren’t just blowing smoke; Tulip has the numbers to prove it.

Achieving Long-Term Success through Kaizen

Kaizen is your buddy for the long haul. It’s not just a flash in the pan but a solid shot at ensuring you’re not just here today, gone tomorrow (Kaizen Institute).

Key factors for keeping it rolling include:

- Sticking with a “keep improving” mindset

- Regularly checking in to tweak processes

- Keeping staff in the loop with fresh training

Companies in it for the long run with Kaizen usually see growth across the board, making for a sturdy business plan. It’s not just momentary wins; it’s about keeping success sustainable.

For tips on building a culture that loves improvement, check out our guide on launching a kaizen culture.

Keep the Kaizen ball rolling to shape an organization that not only thrives in immediate growth but stands the test of time with ongoing gains. Dive into the details with our take on kaizen tools.

Kaizen Success Stories

Kaizen at Toyota: A Case Study

Toyota’s Production System (TPS) proudly showcases the Kaizen way of thinking. Created by Taiichi Ohno, this system sets the bar high for getting the most out of every inch of manufacturing. Ohno’s motto, “some days little up, some days big up,” captures Kaizen’s essence—small, steady steps leading to big improvements.

Toyota’s mastery of Kaizen has brought a slew of wins:

| Improvement Area | Before Kaizen | After Kaizen |

|---|---|---|

| Production Cycle Time | 31 days | 25 days |

| Defect Rate | 2% | 0.5% |

| Employee Suggestions | 10/month | 400/month |

Thanks to Kaizen, Toyota shrunk its production times, slashed defects, and revved up employee suggestions with a dynamic feedback loop. And we’re not just talking numbers—this mindset builds a culture of always getting better and tackling issues head-on.

If you’re chomping at the bit to learn more, dive into kaizen philosophy and kaizen strategies for the full scoop.

Kaizen in Non-Manufacturing Industries

Kaizen isn’t a one-trick pony—it thrives beyond factory floors too. It’s thriving in healthcare, software development, education, logistics, and more.

Healthcare

Kaizen helps hospitals up their game in patient care and operations. Take Virginia Mason Hospital in Seattle—they used Kaizen magic to cut the fluff in processes and boost patient care.

Let’s see some numbers pre and post-Kaizen:

| Improvement Area | Before Kaizen | After Kaizen |

|---|---|---|

| Patient Wait Time | 45 minutes | 15 minutes |

| Medical Errors | 12/month | 4/month |

| Patient Satisfaction | 78% | 95% |

Software Development

In the coding world, giants like GE and Motorola use Kaizen to speed up product creation and better quality checks.

Check out their scoreboard:

| Improvement Area | Before Kaizen | After Kaizen |

|---|---|---|

| Development Cycle Time | 12 weeks | 8 weeks |

| Bug Rate | 30/1000 lines | 5/1000 lines |

| Team Collaboration | Low | High |

Curious about bringing these practices into your line of work? Peek at our articles on kaizen implementation and kaizen tools.

Kaizen’s adaptability proves it’s a winner for continuous improvement, lifting all sorts of industries. If you’re eager for more know-how on reaping these benefits, look into kaizen training programs and kaizen management.

Kaizen Tools and Resources

Getting a handle on the Kaizen improvement process is a game-changer for businesses. It’s about using the right tools and resources to keep things on track and always moving forward. Knowing what’s out there is a must for anyone in charge of making things better, whether it’s in business or on the factory floor.

Vorne XL: Pumping Up Productivity

Enter Vorne XL. It’s your go-to gadget for boosting how things work in Kaizen methodology. This gizmo zaps waste and cranks up Overall Equipment Effectiveness (OEE) like no other. It’s a breeze to set up and packs a punch with powerful features, making it a quick fix for tracking and turbocharging production.

| Feature | What It Does |

|---|---|

| Cost | You pay just once |

| Installation | Fast and straightforward |

| Trial Option | Free to try for 90 days |

| Main Benefit | Keeps an eye on production in real-time |

Vorne XL is all about grabbing data from how things are made, spotting hiccups, and fixing them pronto. It dishes out tasty insights on gear performance and production smoothness, keeping improvement on the roll and making Kaizen second nature.

Kaizen in Daily Grind

Kaizen isn’t just a factory floor thing—it fits into daily work life too. Check out these down-to-earth tips to give work habits a Kaizen twist:

- Standardization: Nail down standard ways of doing stuff to keep things steady and on point. This nips variation and goofs in the bud. Visuals like diagrams and snaps can be your best mate.

- 5S System: Get your workspace in shape with the 5S steps (Sort, Straighten, Sweep, Standardize, Sustain) to stay safe and juiced up with efficiency.

- Lean Manufacturing: Shave off waste like flaws, over-making, and extra moves with lean manufacturing. The aim is to deliver more without burning excess resources.

- SMED Events: Host Single-Minute Exchange of Dies (SMED) events to trim the fat on changeover times by breaking down and smoothing out processes. Expect to chop changeover by up to 50%.

Plug these Kaizen devices and tricks into your daily grind, and watch your workplace turn into an improvement hotbed. For an even deeper dive, sniff around our kaizen principles and kaizen tools pages.

These tools do more than just boost how things run—they’re the backbone for upping worker morale, jacking up productivity, and cranking out better products. To read more about the goodies Kaizen brings, hit up our Kaizen benefits.

Getting these tools and resources in your arsenal can ignite lasting betterment and keep growth rolling in any business.

Key Considerations for Kaizen

Jumping into the kaizen continuous improvement process isn’t like playing hopscotch; it requires some serious thought to make sure it sticks, makes sense, and keeps evolving. Let’s chat about what matters most if you want Kaizen to become a sturdy part of the company mindset.

Keeping Kaizen Going Strong

To keep Kaizen ticking along nicely, it should seep into the fabric of your company like coffee on a white shirt—it’s got to be everywhere, and everyone needs a good handle on what it’s all about. Getting everyone on board with the kaizen philosophy makes it second nature to always be looking for ways to do things better.

Keeping the ball rolling means making sure any fancy new changes don’t fade into the background. By updating how things are done and teaching folks the best ways to do them, improvements won’t just stick around—they’ll thrive. That way, Kaizen isn’t just the newest flavor of the month.

Keeping an Eye on Kaizen’s Pulse

If you’re sprucing things up, it’s handy to know where you started and where you’ve ended up. Jotting things down before and after changes lets you see if you’re moving in the right direction. Knowing your starting point means you can check back later to see how much of a difference you’ve made.

Benchmarks tell you whether you’re getting a bang for your buck, highlight what parts are doing well, and help steer the ship for where to improve next. A few handy tools and metrics should always be at the ready. For instance:

| Metric | Before Improvement | After Improvement |

|---|---|---|

| Cycle Time (minutes) | 15 | 10 |

| Error Rate (%) | 5.2 | 2.4 |

| Employee Engagement Score | 70 | 85 |

Keeping tabs on things lets you see which Kaizen strategies are hitting home runs and which might need a little tweak.

Learning and Growing with Kaizen

For Kaizen to really shake things up, training needs to be in the spotlight. Regular Kaizen training programs help everyone get on board with how to utilize all those nifty Kaizen tools and tricks. This approach ensures everyone marches to the same beat of continuous improvement, and smooth sailing is much more likely.

- Job-Specific Training: Make sure everyone understands what Kaizen means for what they do day-to-day. Tailoring the learning means everyone gets it in a way that makes sense for them.

- Workshops and Seminars: Keeping up-to-date with Kaizen workshops and seminars means no one’s going stale on the latest tricks.

- Hands-On Coaching: Real-time feedback and coaching are like having a GPS for Kaizen; it helps everyone know they’re on the right path and keeps those Kaizen concepts fresh in their minds.

A solid training plan is like planting a seed for a Kaizen mindset, making sure the improvement efforts take root and grow over time.

Focusing on lasting efforts, sharp measurement and monitoring, and top-notch training and development means Kaizen can steer your ship toward long-term success.

Conclusion

Embracing the Kaizen continuous improvement process can be a game-changer for any organization striving for excellence. By ingraining small, consistent changes into your company’s culture, you pave the way for significant advancements in productivity, quality, and employee satisfaction.

From understanding the foundational Kaizen philosophy to implementing practical methodologies like the PDCA cycle and standardized work, each step contributes to a more efficient and harmonious workplace.

The adaptability of Kaizen across various industries—be it manufacturing, healthcare, or software development—demonstrates its universal applicability and effectiveness. Overcoming challenges such as resistance to change and maintaining momentum requires steadfast leadership, continuous training, and a commitment to fostering a culture of transparency and collaboration.

The success stories of giants like Toyota highlight the transformative power of Kaizen, proving that sustained improvement leads to long-term success. As you integrate Kaizen into your operations, you’ll not only enhance your processes but also cultivate a motivated and engaged workforce, ready to drive your organization towards enduring prosperity.

Start your Kaizen journey today and watch your business thrive through continuous, incremental improvements.

FAQs

1. What is Kaizen and how does it benefit businesses?

Kaizen is a Japanese philosophy focused on continuous, incremental improvement in all aspects of an organization. It benefits businesses by enhancing productivity, reducing waste, improving quality, and fostering a culture of employee engagement and collaboration.

2. How can the PDCA cycle be applied in Kaizen?

The PDCA cycle—Plan, Do, Check, Act—is used in Kaizen to implement and evaluate changes systematically. It ensures that improvements are planned carefully, executed on a small scale, assessed for effectiveness, and standardized if successful, creating a loop of continuous improvement.

3. What are Gemba Walks and why are they important?

Gemba Walks involve managers and leaders visiting the actual place where work is done to observe processes firsthand. They are important because they help identify inefficiencies, engage with employees, and gather insights for meaningful improvements.

4. Can Kaizen be applied outside of manufacturing?

Yes, Kaizen is versatile and can be applied to various industries including healthcare, software development, education, and logistics. It helps these sectors improve processes, enhance quality, and increase overall efficiency.

5. What are common challenges when implementing Kaizen and how to overcome them?

Common challenges include resistance to change, lack of understanding, and sustaining efforts. These can be overcome by strong leadership commitment, continuous training, fostering open communication, and recognizing and rewarding employee contributions.