Kaizen isn’t just a business buzzword—it’s a mindset that nurtures consistent progress by celebrating small, steady improvements.

Born in post-war Japan, Kaizen invites organizations to refine their practices every day, from trimming inefficiencies on the production line to reimagining workflows in hospitals.

The true magic lies in its inclusive spirit: everyone from frontline employees to top leadership can share insights and take action. This dynamic synergy fosters a culture where no improvement is too minor to matter.

If you’re looking to drive sustainable success, read on to discover how Kaizen can transform the way you think, work, and deeply innovate.

Understanding Kaizen

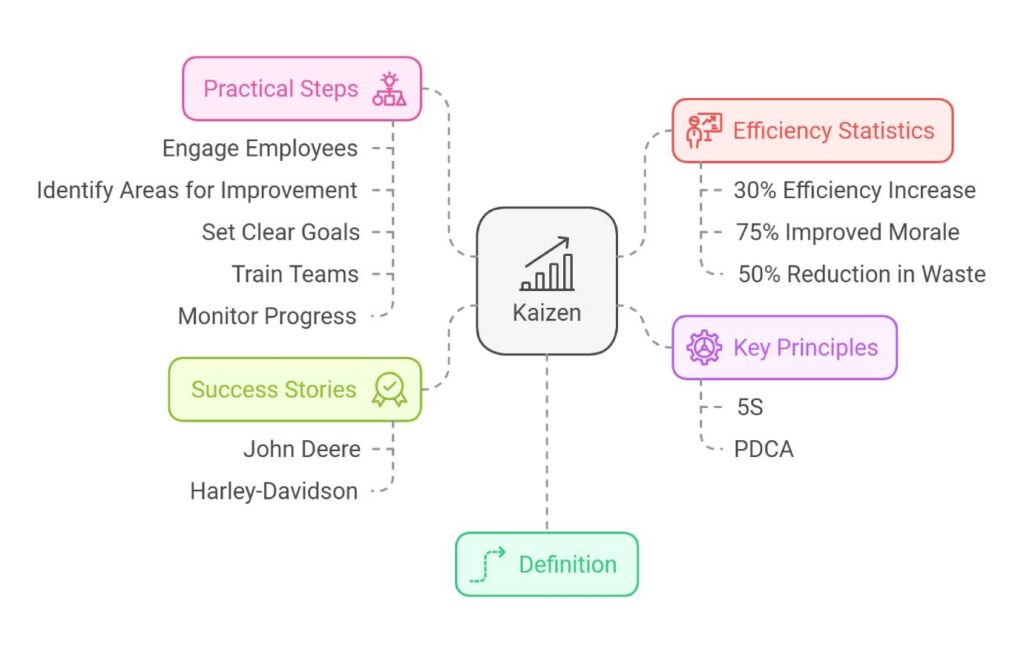

Definition of Kaizen

Kaizen, a word from Japan that means “change for the better,” focuses on never-ending improvement, especially in business. It’s like slowly fixing things one step at a time until you see big results. The whole idea is thinking that there’s always room to spruce things up, and nothing should just stay the same.

You might find folks getting involved in different Kaizen activities, like hanging out in quality circles or doing 5S audits. They’ll also hit up training sessions to pick up new skills to get things to run smoother and faster. If you’re curious about the basics of Kaizen, check out our page on Kaizen philosophy.

Principles of Kaizen

Kaizen’s all about the little tweaks adding up to big gains. Some main ideas it hangs its hat on:

- Continuous Improvement: Always look for ways to improve things, even if it means taking baby steps.

- Respect for People: Listening to everyone’s ideas, getting the team spirit going, and making sure folks feel part of the process.

- Eliminating Waste: Cutting out the fluff to make things run smoother.

Here’s a handy table to spell out the core ideas:

| Principle | Description |

|---|---|

| Continuous Improvement | Keep an eye out for any chance to make things better, even if it means small steps. |

| Respect for People | Appreciate all ideas, nurture teamwork, and encourage collaboration. |

| Eliminating Waste | Find and get rid of activities adding no value to the process. |

A big part of Kaizen is the 5S framework, which focuses on neatness, organization, and keeping things tidy. The goal? Boost profit, efficiency, safety, and service. The 5S steps are:

- Seiri (Sort): Chuck out stuff that’s just taking up space.

- Seiton (Set in Order): Arrange needed items so they’re easy to grab.

- Seiso (Shine): Clean up to keep work areas safe and efficient.

- Seiketsu (Standardize): Set rules to keep up with the first three S’s.

- Shitsuke (Sustain): Make it a habit to stick with these rules over time.

Getting your head around these principles is key to bringing Kaizen into your workplace the right way. For more nitty-gritty details, drop by our pages on kaizen principles and kaizen process improvement.

By living these principles, companies can build a vibe that keeps aiming for better, helping boost how things work and making employees feel more connected. If you’re looking to dive deeper into Kaizen, our Kaizen training programs page is packed with goodies.

Implementing Kaizen

Getting Started with Kaizen

Diving into Kaizen means eagerly jumping into a rhythm of constant betterment, always seeking those little tweaks to keep things moving smoothly. So, how do we kick off this whole Kaizen adventure? Let’s break it down:

- Educate the Team: Start by schooling your crew on what Kaizen’s all about – the ins and outs of its principles. Knowing why tiny, ongoing improvements matter is the first step to winning this game.

- Set Clear Objectives: Figure out what you want Kaizen to do for you. Maybe it’s about making operations slicker or getting folks more involved—having a clear aim makes sure you’re on target.

- Form Kaizen Teams: Get a mixed group together for your Kaizen team; people from all corners of the office. With more perspectives, the ideas will flow like a river.

- Implement Training Programs: Build up your team’s muscles with some Kaizen training. This gives them the tools to apply Kaizen like pros in their daily grind.

- Start Small: Encourage folks to zero in on little things that could work better. These small wins show the power of Kaizen and get everyone pumped.

- Continuous Improvement Cycle: Follow the legendary seven-step habit for continuous improvement:

- Spotting problem areas

- Analyzing these hiccups

- Cooking up solutions

- Putting those solutions to work

- Checking out the results

- Making the successful fixes stick

- Rinse and repeat

With these moves, you’re laying the groundwork for a mighty Kaizen takeover.

Tools for Kaizen Implementation

To pull off Kaizen smoothly, you’ll need some tools to help you move through this process like a pro. Check these out:

- 5S: A five-step clean-up crew—Sort, Set in order, Shine, Standardize, and Sustain. It’s all about setting up a workspace that’s organized and ready for action.

| Stage | Description |

|---|---|

| Sort | Chuck what’s unnecessary |

| Set in order | Line up essential stuff for a quick grab |

| Shine | Make your area sparkle |

| Standardize | Create and stick to procedures |

| Sustain | Keep doing it, keep improving |

- Quality Circles: A group huddle where employees gather to talk shop and sort out work issues. It’s like team building but with purpose!

- PDCA Cycle: The beloved Plan-Do-Check-Act routine is all about taking control and making things better—a quick four-step workout that keeps things in line.

- Kaizen Events: Think of these as sprints—short and focused projects that bring about speedy changes.

- Visual Management: Utilize tools like charts, graphs, and boards to easily show what’s going down, nipping problems in the bud at a glance.

There’s plenty more to explore on Kaizen tools in our detailed guide on kaizen tools.

Riding these strategies and tools, organizations can embed Kaizen right into their daily routine, leading to a culture that’s always leveling up. Whether in a factory or a hospital, leaning into Kaizen means real, meaningful change.

Examples of Kaizen Success

Kaizen, the ongoing effort to improve, is like a secret sauce for many companies. Let’s dive into how this nifty practice has worked wonders for the big shots like John Deere and Harley-Davidson.

Case Study: John Deere

John Deere, those folks making tractors and other agricultural gizmos, really hit a home run with Kaizen. They revved up their game with smart, automatic systems to boost their product checks. The result? They found flaws quicker and sorted them out faster.

Here’s the scoop on Kaizen’s magic at John Deere:

- Speeding Things Up: They cut down the time it takes to check stuff.

- Eagle-Eyes for Quality: Got sharper at catching errors.

- More Bang for Their Buck: Managed to look at more products in a flash.

John Deere proved that a bit of tech and Kaizen can do wonders for quality control. Curious about more ways Kaizen can pep up your processes? Check out Kaizen process improvement.

Case Study: Harley-Davidson

Now, Harley-Davidson, the king of cool rides, jumped headfirst into Kaizen too. They embraced a bunch of tricks like Total Productive Maintenance (TPM) and the 5S System, along with Six Sigma and more. These strategies really jazzed up their output and kept everything smooth as their bikes on the highway.

Tools in Harley-Davidson’s toolkit:

- Total Productive Maintenance (TPM)

- 5S System

- Standard Work

- Six Sigma

- Just-in-time Inventory Management

- Value Stream Mapping

What Harley-Davidson scored with Kaizen:

| What Got Better | How They Did It |

|---|---|

| Get More Done | They smoothed things out in the production line |

| Faster Delivery | Thanks to smart timing and stock handling |

| Travel Budgets Shrank | Using clever path planning |

| Sticking to Great Techniques | With some no-nonsense rules from Standard Work and Six Sigma |

Harley-Davidson lived and breathed Kaizen, using its ideas to build bikes and keep speeding forward. Want to know more about how they nailed it? Jump into our kaizen methodology.

Whether we’re talking tractors or motorcycles, Kaizen’s had a real kick in improving how companies like John Deere and Harley-Davidson keep things rolling smoothly. If you’re looking to jazz up your own operations, putting continuous improvement Kaizen in the mix might just be your ticket.

Kaizen Methodology

Dive into the world of Kaizen methodology, where the magic happens through continuous improvement. Two big players in this game are the PDCA Cycle and Kaizen workshops, making the world just a bit better, one step at a time.

The PDCA Cycle

The PDCA (Plan-Do-Check-Act) Cycle is like the bread and butter of Kaizen. It’s all about making steady progress by following a set routine of steps. Think of it like your favorite playlist on repeat, but it’s your business moving up the ladder instead.

| Step | Description |

|---|---|

| Plan | Set your goals and sketch out a solid plan to reach them. Be sure to jot down the steps and figure out what you need. |

| Do | Give your ideas a go on a small scale. Keep an eye on what happens and gather info along the way. |

| Check | Take a good look at your data. Did you hit the mark? Spot any hiccups or missing pieces? |

| Act | Use what you learned to lock in the wins or tweak things and try again. Spin into the next cycle with a fresh game plan. |

This cycle is like a trusty problem-solving buddy who likes to keep things going smoothly without any fuss. Each spin around the cycle is like building a tower, one block at a time, inching closer to betterment. Wanna get deeper into Kaizen’s secrets? Check out our kaizen methodology article.

Kaizen Events and Workshops

Kaizen events, along with their blitz or workshop variations, are like short but intense sprints toward improvement. These shindigs target particular hurdles and gather a few hands from your team (usually no more than 50) to make some magic.

Types of Kaizen Events

| Event Type | Description |

|---|---|

| Kaizen Blitz | A quick, high-impact sprint to score some fast wins and leave a mark. |

| Kaizen Workshops | Well-organized gatherings where folks learn and get involved in Kaizen’s ways. |

Now, these events come armed with some cool tools:

- 5S Framework: Spruces up your workspace and makes things tick like clockwork.

- Total Productive Maintenance (TPM): Keeps your gear in top shape to dodge any glitches.

- Value Stream Mapping: A neat way to visualize how stuff moves from the start to the finish line.

These gadgets are the unsung heroes pushing process enhancements and quality jumps. Need pointers for rocking a Kaizen event? Peek at our kaizen workshops guide.

Clinging onto Kaizen through the PDCA Cycle and laser-focused events helps businesses sharpen their operations. Little by little, it weaves a culture that’s all about getting better every day. Hungry for more on keeping kaizen practices alive and crafting a kaizen culture? Swing by our site.

Benefits of Kaizen

Kaizen’s got some solid perks for companies aiming to keep things fresh and top-notch. Two major wins with Kaizen: making operations smoother and getting the team more pumped and engaged.

Operational Efficiency

Kaizen’s all about those tiny tweaks rather than sweeping overhauls. It’s like making microscopic, but mighty fixes with what you’ve got, sidestepping any major shake-ups.

Here’s what the Kaizen philosophy hones in on:

- Figuring out what your customer truly wants

- Smoothing things out to zap any process hiccups

- Taking Gemba walks to snag insights from the frontline

- Giving everyone a seat at the table to pitch ideas

- Pushing for no-nonsense chats among the crew

Following these steps can level up how efficiently things get done—amping up quality and the big picture stuff. When procedures get the Kaizen touch, businesses see slicker workflows, less waste, and trim expenses. Tools like value stream mapping and Total Quality Management give that extra nudge to squash any bloat.

Employee Engagement

With KAIZEN™, it’s like planting a garden of constant betterment, where everyone digs in to spot issues, suggest plans, and roll up their sleeves. This vibe makes employees feel they’ve got some skin in the game, upping their passion for the company’s dreams.

Getting folks into Kaizen shenanigans perks up job satisfaction ’cause it feels good to be heard. It cranks up the good vibes and team spirit. Plus, staying in the loop with Kaizen activities keeps folks on their toes, always learning, crafting new ideas, and hustling towards improvements.

When employees dive into Kaizen practices, you end up with a fired-up crew, eager to push the needle on both personal and company performance. For a deeper dive into getting Kaizen off the ground and its goodness, check out our pieces on Kaizen training and Kaizen implementation.

Kaizen in Different Industries

Kaizen, a method of continuous improvement, is making waves in a variety of sectors. Let’s peek into how Kaizen is shaking things up in manufacturing and healthcare.

Kaizen in Manufacturing

Hailing from post-war Japan and championed by Toyota, Kaizen is at the heart of Lean Manufacturing. Instead of one-time big-bang changes, Kaizen opts for tiny, gradual tweaks aimed at boosting efficiency and kicking waste to the curb.

Core Aspects of Kaizen in Manufacturing:

- 5S Framework: Think cleanliness meets orderliness. This boosts safety, cuts down clutter, and streamlines service.

- PDCA Cycle: The old faithful, Plan-Do-Check-Act cycle, keeps those changes cooking just right.

- Total Employee Participation: It’s all hands on deck, from the big bosses to the shop floor crew, knitting a culture of never-ending betterment.

| Aspect | Key Benefits |

|---|---|

| Waste Reduction | Slices inefficiencies at each production stage |

| Employee Engagement | Pitches everyone into the process of improvement |

| Efficiency | Banks on small tweaks that add up to big wins over time |

Wanna see Kaizen at work in manufacturing? Hop over to our piece on kaizen for manufacturing.

Kaizen in Healthcare

In the world of healthcare, Kaizen is like a superhero fighting to enhance patient care, smoothen operations, and stomp out errors. Its knack for small, steady improvements makes it a perfect match for healthcare’s precision-driven vibe.

Kaizen Magic in Healthcare:

- Process Tightening: Evens out the bumps in clinical procedures to slash errors.

- Patient Flow Fixes: Smoothens the movement of patients, trimming wait times.

- Error Busting: Zeros in on and zaps care process errors.

Hospital Example: Take a hospital eyeing quicker check-ins. By dissecting each check-in step, staff can weed out bottlenecks, implant tiny tweaks, and voilà – folks check-in faster and smoother.

| Improvement Area | Possible Wins |

|---|---|

| Patient Check-In | Slashes wait times, amps up patient happiness |

| Medication Handling | Lowers slip-ups, cranks up patient safety |

| Surgery Procedures | Rounds off processes to better outcomes |

Wanna dig deeper into healthcare magic? Check out our take on kaizen in healthcare.

When Kaizen wiggles into these industries, it sparks a culture of ongoing betterment, driving up operational oomph, rallying employee enthusiasm, and boosting service quality. Looking to explore more on Kaizen? Check out our hubs on kaizen principles and kaizen tools.

Sustaining Kaizen Practices

Keeping Kaizen alive and kicking in a company means keeping the improvement train rolling and making everyone feel like they own a piece of it. Let’s chat about how to make a Kaizen-friendly vibe and keep things ever-improving with these good ol’ Kaizen ideas.

Building a Kaizen Culture

Making a Kaizen-friendly space is the secret sauce for any long-haul improvement gig. When everyone’s on board with Kaizen, employees get the power to sniff out what’s not working and come up with better ways to do things.

Here’s how to get that Kaizen vibe going:

- Get Everyone in the Mix: Push all team members to toss in their two cents to make things better. This gives them a sense of “I own this thing” and they’re more likely to pitch in (Kaizen Institute).

- Train, Train, Train: Offer cool kaizen training programs so that everyone knows the ropes and can put those Kaizen tricks to work.

- Props for Effort: Give a high five to those who jump on the improvement train and make a difference.

- Keep Talking: Set up regular kaizen workshops and gabfests to talk shop, share big wins, and cheer on each other.

Continuous Improvement with Kaizen

At the core of Kaizen is doing a little better all the time. Making sure this never stops means sticking to a few key habits:

- Keep on Rolling with PDCA: Use the good old PDCA (Plan-Do-Check-Act) to keep your problem-solving and improvement formal and steady. This cycle keeps checking and tweaking improvements.

| PDCA Cycle | Description |

|---|---|

| Plan | Figure out what needs fixing and come up with a game plan. |

| Do | Try out your game plan on a small scale first. |

| Check | See how it went. Measure twice, just like Dad taught you. |

| Act | If it worked, go big or tweak and try again. |

- Stick to What Works: Lock in best practices with Standardized Work, and keep using Kaizen tools to spot more improvements.

- Say Yes to Empowerment: Give your crew the green light to call out problems and come up with fixes themselves. It’s all about making a group of go-getters ready to bust out some innovation.

- Keep Those Notes Handy: Scribble down what changes were made and ask your team what they think about it, just to make sure the improvements really stick to the day-to-day.

If you want to dig deeper into why these practices work and how to nail them down, check out the Kaizen process improvement guides or get the lowdown on Kaizen methodology.

Jumping into and sticking with Kaizen is saying “yes” to never-ending growth. By nailing down a Kaizen culture and pushing continuous improvement, companies can ride the wave of success and smarts for the long haul.

Evolution of Kaizen

From Japan to the West

Kaizen, the big cheese of ongoing improvement, started in post-war Japan. Folks over there were itching to boost the quality of their stuff and the efficiency of their work. Toyota got the ball rolling in May 1951 with their Creative Idea Suggestion System, planting the seeds for the Kaizen we know today.

American brainiacs like W. Edwards Deming tipped the scales by bringing quality control to Japanese companies. Kaizen at its heart is about everyone chipping in for non-stop betterment. Japanese workers, especially at Toyota, rallied in quality circles to cut waste, dodge defects, and kindle innovation.

Kaizen made its splash in the West when Masaaki Imai’s book “Kaizen: The Key to Japan’s Competitive Success” hit the shelves in 1986, unlocking the doors to Western enterprises. Since then, it’s been a staple in lean manufacturing, famously feeding into Toyota’s way of working.

The Future of Kaizen

Looking ahead, Kaizen seems to have a bright road ahead as folks continue their hustle to up their efficiency game and nurture ongoing improvement. With tech evolving at warp speed, digital tools and data are becoming the sidekick to Kaizen practices. These gadgets provide instant smarts, helping us make faster and wiser choices.

Kaizen’s knack for adaptability shows as it’s being molded to fit not just factories but also healthcare, education, and software development. This flexibility underscores Kaizen’s power in diverse fields. Plus, the push for involving the whole team and giving them a say makes it a go-to approach for organizations eager to boost their culture and operational savvy.

In a world where everyone’s vying to be the top dog, Kaizen serves as a blueprint for ongoing fine-tuning, teaming up nicely with lean and agile management styles. Its knack for small, steady tweaks ensures companies stay nimble and ready for whatever the market throws at them.

Key Factors for Sustaining Kaizen

To keep Kaizen alive and kicking, businesses need to concentrate on:

- Creating a Kaizen Groove: Promoting a vibe of constant betterment from the top to the bottom.

- Education and Skill-Building: Rolling out kaizen educational efforts so everyone gets clued up and skilled.

- Frequent Kaizen Shindigs: Hosting Kaizen workshops and such to keep the momentum rushing forward.

- Bosses on Board: Making sure leadership not only cheers from the stands but gets in the game and backs Kaizen fully.

By zeroing in on these aspects, businesses can hang onto the perks of Kaizen and keep tweaking their operations for the better. For more nuggets on keeping Kaizen thriving, check out our article on building a Kaizen culture.

Conclusion

Kaizen’s powerful message—that consistent small steps lead to monumental gains—has shaped industries across the globe.

By encouraging organizations to identify inefficiencies, empower employees at all levels, and adopt robust frameworks like PDCA and 5S, Kaizen lays down a roadmap for transformative success.

Whether it’s John Deere accelerating flaw detection or Harley-Davidson perfecting production lines through integrated approaches like Six Sigma, the principle remains the same: progress is never out of reach when everyone is involved.

Kaizen has also proven its mettle in sectors like healthcare, where streamlined patient flow and reduced wait times directly enhance quality of care.

Maintaining a Kaizen culture means nurturing open dialogue, celebrating everyday wins, and constantly reexamining processes to spot new opportunities.

By embedding Kaizen into daily routines—through small, iterative steps—organizations can remain agile, innovative, and ready to tackle future challenges.

Ultimately, embracing Kaizen is about creating an ever-evolving workplace where steady improvement becomes second nature.

FAQ

What is Kaizen and why is it essential?

Kaizen is a Japanese philosophy of continuous improvement that encourages small, incremental changes to boost efficiency, quality, and employee engagement.

How does Kaizen differ from other improvement methods?

Unlike large-scale, one-time overhauls, Kaizen emphasizes steady, ongoing tweaks. This approach reduces risks and fosters a culture of collective ownership.

Where can Kaizen be applied?

Kaizen is versatile: it’s applied in manufacturing, healthcare, software development, and even personal development. Anywhere efficiency and quality can be improved.

What are the core tools used in Kaizen?

Common Kaizen tools include 5S for organizing workspaces, the PDCA cycle for iterative improvements, and Kaizen events for rapid, focused problem-solving.

How do companies sustain Kaizen long-term?

By embedding Kaizen into their culture through training, leadership support, frequent workshops, and continuous recognition of employee contributions.

Final thoughts

Kaizen isn’t just a process—it’s a guiding philosophy that empowers organizations to strive for betterment every day.

By sharing knowledge, welcoming employee insights, and sustaining that momentum through transparent communication and leadership support, businesses can maintain a cycle of improvement that never stops.

Whether you’re cleaning up a chaotic production floor, trimming delays in patient care, or boosting your software development cycle’s pace, Kaizen’s inclusive and iterative model helps teams adapt, learn, and evolve.

Each small success is a stepping stone to bigger wins down the line, eventually creating a work culture that values continuous progress over complacency.

Main Tips

- Start with small changes and celebrate quick wins.

- Offer training and empower every employee to spot improvements.

- Use visual tools (charts, boards) for transparency and motivation.

- Keep the PDCA cycle in motion—never stop refining and revising.

- Involve leadership to champion continuous improvement initiatives.

Recommended Products and Accessories

- “Kaizen: The Key to Japan’s Competitive Success” by Masaaki Imai – Foundational reading.

- Whiteboard & Sticky Notes Bundle – Perfect for brainstorming and daily improvement tracking.

- 5S Labeling and Tool Organizers – Helps maintain tidy and efficient workspaces.

- PDCA Cycle Posters – Visual reminders to keep improvement top-of-mind.

- Digital Project Management Software (e.g., Trello, Asana) – Facilitates planning and collaboration.

All these resources and items support Kaizen’s continuous improvement framework, helping you stay organized, motivated, and consistently focused on what can be better.