Imagine a workplace where every small improvement sparks a wave of efficiency and innovation. Welcome to the world of Kaizen in manufacturing—a philosophy that transforms ordinary factories into powerhouses of productivity.

Born in post-war Japan, Kaizen emphasizes continuous, incremental changes driven by teamwork and creativity. Whether you’re a seasoned manager or a new employee, embracing Kaizen can revolutionize your operations, eliminate waste, and boost morale.

Dive into our comprehensive guide to discover how this timeless strategy can propel your manufacturing processes to new heights, aligning seamlessly with both user experience and search engine optimization.

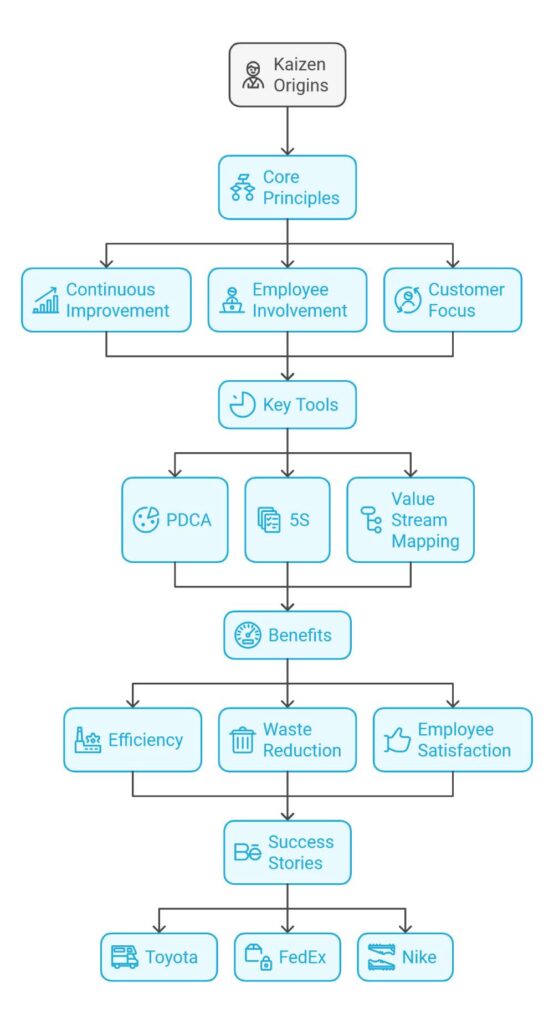

Understanding Kaizen

History and Origins

Kaizen, a Japanese idea meaning “make things better,” sprang up after World War II to tackle issues in factories struggling to meet change head-on. It’s got Masaaki Imai’s fingerprints all over it, as he put it on the map over 30 years ago.

This method pushes for ongoing improvement, getting rid of waste, upping productivity, getting everyone on board, and sparking some good old-fashioned creativity. Now, it’s a cornerstone everywhere in lean manufacturing and business strategies.

Key Concepts Explained

At its heart, Kaizen is all about teamwork, with people at every level pitching in and making things a smidge better every day. This kind of effort becomes the secret sauce for a company to thrive. Some big ideas here are:

- Keep Getting Better: Never stop trying to make things work smoother and faster.

- Everyone’s Input Matters: Every suggestion counts, no matter who you are.

- Baby Steps: Small adjustments today can add up to big wins tomorrow.

- Quality Circles: Groups of workers who regularly brainstorm and fix issues.

- 5S Audits: A tidying-up system meaning Sort, Set in order, Shine, Standardize, Sustain.

- Always Learning: Keep everyone up-to-date with the latest tricks of the trade.

Principles of Kaizen

At its core, Kaizen is about setting up everything for success. Here are some basics:

- Set Standards: Lock in the best way to do things and stick to it.

- Cut Out Clutter: Spot and drop anything that’s dragging you down.

- Get it Right the First Time: Nail each task the first go-round.

- Keep Things Moving: Maintain a steady workflow to sidestep holdups.

- Power to the People: Employees should feel like their voices matter.

- Team Spirit: Encourage working together, not just side by side.

The PDCA cycle is the game plan:

- Plan: Set what you’re aiming for and note what might help.

- Do: Get those changes up and running.

- Check: See what’s working or what ain’t and jot it down.

- Act: Tweak it, fix it, try again.

Ready for more on making this work? Jump into our piece on kaizen methodologies and get into the nuts and bolts of kaizen principles that keep it rolling.

When everyone is geared towards these principles, Kaizen builds a better culture that takes significant leaps in not just manufacturing but whatever you’re up to. To dig deeper into getting started, check out our info on kaizen implementation.

Kaizen in practice

Getting a grip on Kaizen magic? It can seriously shake up your manufacturing game for the better. You’ll see your efficiency shoot through the roof by playing it smart with tried-and-true methods and some clever tools.

Implementing Kaizen

Rolling out Kaizen in your manufacturing spot means a step-by-step game plan. It kicks off with:

- Spotting Room for Improvement: Everyone from the top boss to the newbie on the floor is in on the action. Together, they sniff out what needs fixing, fueling a vibe of constant betterment.

- Getting Everyone Onboard: Make sure you rally the troops in the Kaizen movement. Everyone’s viewpoint counts, and harnessing the gang’s cleverness just makes everything better (kaizen team).

- Setting Goals You Can Reach: Map out goals that are clear and within grasp. Guidance comes easy when everyone knows where they’re headed (kaizen implementation).

Kaizen Methodologies

Kaizen’s secret sauce is in its tactics. Take the PDCA cycle, for instance:

- Plan: Pick out what needs tweaking and draft your game plan.

- Do: Give your plan a test run on a small scale to see if it holds water.

- Check: Look at how things went and sort out any hiccups.

- Act: If it’s working, scale it up. If not, tweak the plan and go again.

This way, you’re not just winging it—you’re making improvements based on rock-solid proof.

Another ace in the hole is Standardized Work, a living document of what works best at any given moment. It shifts as each Kaizen move does its thing.

Kaizen Tools

You need to have the right gear for the gig. Check out these Kaizen power tools:

- 5S (Sort, Set in Order, Shine, Standardize, Sustain): Your go-to for keeping things shipshape.

- Value Stream Mapping: Spot and snip out any waste in the works.

- Fishbone Diagrams (Ishikawa): Dig deep to root out problem causes and craft some solid solutions (kaizen tools).

- Gemba Walks: Supervisors hit the shop floor to catch the action and get the lowdown on the hustle.

| Tool | Purpose |

|---|---|

| 5S | Keep workspaces neat and tidy |

| Value Stream Mapping | Trim the waste |

| Fishbone Diagrams | Work out the root cause |

| Gemba Walks | Get out there to see everything in action |

With tools in hand, inefficiencies scatter like they’ve been busted by the boss—creating a workplace where everyone is always in for the win (continuous improvement kaizen).

Kaizen’s all about that endless, little-by-little progress, pulling in everyone on the squad, sticking to no-fail strategies like PDCA and Standardized Work, and using cool tools to keep growing and crushing it in the factory.

Kaizen Success Stories

Kaizen at Toyota

Toyota’s not just about cars; they’ve truly championed the Kaizen mindset to make everything tick like clockwork. Their legendary Toyota Production System (TPS) packs three powerhouse tactics: jidoka to keep goof-ups in check, Kaizen for those never-ending tweaks, and just in time to keep the parts parade rolling smoothly.

With these tricks up their sleeve, Toyota’s all about trimming the fat from how they build cars, making sure every ride has that gleam of quality.

| What They Use | What It Does |

|---|---|

| Jidoka | Cuts down on slip-ups |

| Just-in-Time | Keeps inventory just right |

| Kaizen | Always looking for a better way |

Curious how the kaizen way drives Toyota’s big machine? Our deep dives are ready for you.

FedEx Express’s Lean Strategies

When FedEx Express wanted to jazz up their game, they went all in with lean ideas. They shook up aircraft maintenance by adding milestone checks in the C-check process—turns out, this move is a real time and energy saver. It means fewer headaches and more smiles for FedEx, keeping their promise of top-notch service.

| What They Did | What They Got |

|---|---|

| Added Milestones in C-checks | Saved time and sped things up |

For the skinny on FedEx’s lean moves, bounce over to our articles with the full scoop.

Nike’s Continuous Improvement

Nike laced up the Kaizen spirit to stay on top of the game. Back in 2011, they whipped up the Manufacturing Index to nip waste in the bud and level out the bumps in making stuff. Their secret sauce? Lean ideas like “just-in-time” production. For Nike, it’s not just about better kicks—it’s about going green and doing right by the planet.

| What They Kicked Off | What It’s About |

|---|---|

| Manufacturing Index | Slashing waste & fixing flubs |

| Just-in-Time Production | Smoothing out how things get made |

For a closer look at Nike’s Kaizen groove, we’ve got some reading lined up for you.

These tales show how small fixes and constant tinkering under the Kaizen banner can turbocharge a company’s efficiency and keep quality in the fast lane. Hungry for more Kaizen intel? Check out kaizen tips and tricks, kaizen gadgets, and kaizen fix-ups.

Benefits of Kaizen

Kaizen, when done right, can transform manufacturing like a magic trick for companies. Let’s break it down into three main perks: working smarter, wasting less, and giving employees a happier place to clock in.

Increased Efficiency

Picture this: trimming the fat off the workday by ditching the over-the-top tasks you dread. That’s Kaizen working its charm. Take a Sony plant in Indiana; they managed to cut production time in half, making the grind easier for everyone. It’s all about a never-ending loop of “how can we make this better?” that gets everyone from the boss to the newbies aiming for a more streamlined hustle.

| Impact Area | Benefit |

|---|---|

| Production Time | Cut by 50% |

| Employee Strain | Tasks Made Simpler |

| Workflow | Turbocharged Efficiency |

Curious about how it all stacks up? Check out Kaizen process improvement for more juicy details.

Waste Reduction

Kaizen is like a super-sleuth, sniffing out waste and tossing it overboard. Inspired by the Toyota Production System, it finds those pesky hold-ups and clears the clutter like a pro (ClickUp). Imagine a hospital in Washington that shaved ER prep time down with some nifty re-org action. Or a Californian company sprucing up order tracking so slip-ups become a rare breed.

| Examples | Waste Busting Moves |

|---|---|

| Hospital | Whittled Down ER Prep Time |

| Californian Company | Jazzed Up Order Tracking |

Ready to dive deeper? Swing over to our lean kaizen corner and get the full scoop on waste trimming.

Enhanced Employee Satisfaction

Kaizen isn’t just a tool—it’s a vibe that turns the workplace into a buzzing hive of problem-solvers. It lifts employees’ spirits by letting them roll up their sleeves and tackle hurdles head-on, sparking conversations and teamwork throughout the company. This collaborative atmosphere leads to employees feeling more valued and customers getting top-notch experiences.

| Benefits | Boosted Job Joy |

|---|---|

| Problem-Solving Ownership | On the Rise |

| Workplace Communication | Revved Up |

| Employee Happiness | On the Up-and-Up |

For a peek into making work feel less like work, hit up our kaizen principles section for tips and tricks.

Wrap-Up Table

| Benefit Area | Game-Changers |

|---|---|

| Efficiency | Shrunk Production Time, Easier Tasks |

| Waste Reduction | Saved Bucks, Spiffed-up Order Handling |

| Employee Satisfaction | More Team Spirit, Smoother Chats |

All in all, Kaizen’s here to keep businesses in a permanent state of awesome. Want to be in the know? Dive into our kaizen benefits guide for all the juicy deets.

Kaizen Techniques

Getting the hang of Kaizen isn’t just smart—it’s essential for non-stop improvement in manufacturing. So, let’s break it down: we’re talking PDCA Cycle, Standardized Work, and Gemba Walks.

PDCA Cycle

Ever heard of Deming? Well, the PDCA Cycle stands for Plan, Do, Check, and Act. This isn’t just biz talk; it’s a practical, down-to-earth way to solve problems and make things better. Used like crazy in Kaizen shindigs, it splits big efforts into baby steps that pack a punch.

- Plan: Figure out what’s going wrong and dream up a solution.

- Do: Test it out on the smallest level.

- Check: See if your idea shines or flops.

- Act: If it’s a winner, go full throttle; if not, tweak it and give it another whirl.

| Stage | Description |

|---|---|

| Plan | Spot the problem, draw up a game plan. |

| Do | Give the plan a go on a tiny scale. |

| Check | Measure what happened against what you hoped. |

| Act | Roll out if it works, rethink if not. |

Want to know more about what makes these cycles tick? Head over to our kaizen methodology.

Standardized Work

Think of Standardized Work like your rulebook for Kaizen. It locks in top-notch methods and makes sure everyone’s singing from the same hymn sheet. By spelling out every process, finding the coolest way to do stuff, and schooling employees on these standards, Kaizen is all about touching up these methods as time goes on.

- Defining Best Practices: Nail down the slickest way to get things done.

- Documentation: Put it all in writing—easy to get and use.

- Training: Get everyone on board with the standard ways.

- Continual Improvement: Keep sprucing up the playbook for a smooth operation.

| Element | Role |

|---|---|

| Best Practices | The top way to handle tasks. |

| Documentation | Written rules and routines. |

| Training | Bringing everyone up to speed on these methods. |

| Improvement | Constant buffing up of the practices. |

To dive into Standardized Work, peek at our guide on kaizen practices.

Gemba Walks

Now, Gemba Walks—this is where Kaizen gets real. Bosses get out from behind their desks and into the heart of the action—the “Gemba”—to see and chat with the crew. This real-world check-in helps pick out what needs fixing and boosts that never-ending drive for betterment.

- Observation: Managers scope out the action up close.

- Engagement: Swap stories and ideas with the staff.

- Identification: Pinpoint snag points and improvement spots.

- Implementation: Use the intel to hammer out better processes.

| Step | Activity |

|---|---|

| Observation | Scope out the work in real time. |

| Engagement | Jaw with workers about their duties. |

| Identification | Zero in on problem areas. |

| Implementation | Tweak the setup based on what you find. |

Eager to learn more about Gemba Walks? Check the scoop in our Kaizen tools article.

Cranking up Kaizen tactics like PDCA Cycle, Standardized Work, and Gemba Walks will supercharge how things roll in the manufacturing world. Eager for more tips and tricks? Explore all things Kaizen in our Kaizen strategies section.

Kaizen in Manufacturing

Think of Kaizen as a tiny superhero for factories, swooping in to boost efficiency and keep cash in your pockets. Here’s your guide to how Kaizen kicks things up a notch in manufacturing.

Kaizen for Operational Excellence

At the heart of Kaizen lies the idea of always getting better—kinda like your Grandma’s stew that improves every time she makes it. It’s about everyone in the team making a little tweak here or there, spotting hiccups, and fixing them, which means happier folks and better goodies flowing out the door.

Now, there’s this thing called the PDCA Cycle—short for Plan, Do, Check, Act. It’s like a systematic approach to dealing with those little pesky problems. First, you sniff out what’s not going right in the “Plan” part. Then you roll up your sleeves during “Do,” trying out solutions on a small scale. In the “Check” part, you see what worked. And in “Act,” you weave those good bits into your daily routine.

Following this recipe helps ferret out what’s not working, fine-tune how things run, and ensure every step is worth its salt.

Cost Reduction Strategies

Using Kaizen isn’t just about looking busy; it’s a money-saver too. By continuously polishing up processes, companies end up cutting back on unnecessary expenditures and churning out more stuff.

Take a leaf from the book of a Sony plant in Indiana. They slashed production time in half using Kaizen, easing employee workloads and untangling complexities. Here’s how Kaizen saves the day:

- Waste Less: Find and scrap items like too much stock, idle time, and flawed products.

- Smoother Workflow: Trim tasks to keep gears turning without hitches.

- Resource Savvy: Use stuff smarter, wasting less material and energy.

These moves don’t just cut costs—they up product quality and employee spirits, making for a happier workspace and more satisfied customers. For more deets, check our piece on Kaizen process improvement.

Incorporating Kaizen wisecracks open communication and teamwork among your crew, sharpening problem-solving skills. For more tricks, pop over to our page on kaizen strategies.

| Kaizen Goodness | Manufacturing Payoff |

|---|---|

| Works Faster | Speeds up production, refines processes |

| Trims the Fat | Slashes overproduction, cuts inventory costs |

| Boosts Morale | Happier workers, better teamwork |

For those hungry for nitty-gritty details, scope out our pages on kaizen tools and kaizen workshops. Adopting Kaizen is like having a secret sauce for manufacturing—driving excellence and steady growth.

Sure, let’s give this a zing and break it down into snippets packed with understanding and a malt of humor.

Types of Kaizen Events

Kaizen events are like the secret sauce that makes manufacturing run smoother. There’s a flavor for every situation. We’re talking Point, System, Line, and Plane Kaizen – sounds like a band, right?

Point Kaizen

Imagine your car breaks down and you need to fix that flat tire, pronto. That’s Point Kaizen for you – quick fixes on the fly! It’s for those tiny glitches that pop up while you’re elbow-deep in work. No time wasted; just roll up those sleeves and sort out the small stuff fast.

| Feature | Description |

|---|---|

| Focus Area | Fix the tiny things |

| Duration | Quick fixes |

| Examples | Machine tantrums, tweaking workflow |

Curious about how to arm yourself with the best tools for these instant fixes? Check our Kaizen tools.

System Kaizen

Now, if you’re looking at something more grandiose, System Kaizen is your go-to. Consider this your master plan. It’s all about tackling the big kahunas – think of turning a cruise ship around. Perfect for strategies that have their sights on the distant horizon.

| Feature | Description |

|---|---|

| Focus Area | Big picture problems |

| Duration | Marathon |

| Examples | Revamping quality checks, onboarding new tech everywhere |

Does this behemoth of strategy tickle your fancy? Dive into our kaizen system.

Line Kaizen

Ever played dominos and watched ’em line up perfectly? That’s Line Kaizen. It’s all about joining the dots between departments and making them sing the same tune. You’ll see operations running like a well-oiled machine.

| Feature | Description |

|---|---|

| Focus Area | Teamwork makes the dream work |

| Duration | Medium haul |

| Examples | Syncing schedules, linking supply chains |

Want more on turning your line into a harmony machine? Tap into kaizen management.

Plane Kaizen

Alright, for the grand finale. Plane Kaizen is about shining a big ol’ spotlight on the whole operation from A to Z. Think of giving an entire orchestra a new score. It’s about large-scale alterations that take the show from good to Grammy-winning.

| Feature | Description |

|---|---|

| Focus Area | Full-stage overhaul |

| Duration | Long road |

| Examples | Redesigning layouts, upgrading the tech ensemble |

Thirsty for a grand strategy to steer your ship? Our lean kaizen is where you head next.

Figuring out which Kaizen is your jam can put you on the fast track to perpetual improvement in manufacturing. Use Point, System, Line, and Plane Kaizen, and your operations will be moonwalking into success.

Hanker for more mind-expanding Kaizen goodies? Swing by kaizen philosophy and kaizen principles – it’s knowledge buffet time!

The 5S Methodology in Kaizen

The 5S strategy is a star player in the kaizen system, aiming to whip your workspace into shape with visual tidiness, organization, cleanliness, and some good ol’ standardization.

Sort

Think of Sort like Marie Kondo for your office. Go through everything; decide what’s crucial and what’s just taking up space. If it’s not essential, it’s outta there! Sorting clears the chaos, giving you a zen-like focus.

Steps:

- Pinpoint the must-haves.

- Toss the non-essentials.

- Neatly stash tools and materials.

Set in Order

Set in Order is about finding a home for everything and sticking to it! This is your chance to organize like a pro, making sure everything’s right where you left it and easy to grab when you need it.

Steps:

- Reserve spots for each item.

- Slap labels on for quick identification.

- Tuck tools in an easy-to-reach setup.

Shine

Shine is where you channel your inner clean freak. Sweep through daily, keep everything spick-and-span, and lend an ear to your mama’s voice echoing, “Cleanliness is next to godliness!”

Steps:

- Give the workspace a daily scrub.

- Check tools and gear for sprucing up.

- Keep those floors and surfaces free of grime.

Standardize

With Standardize, you’re setting some house rules. Make sure everyone’s playing from the same playbook to keep the good vibes from Sort, Set in Order, and Shine flowing.

Steps:

- Lay down the law with guidelines and checklists.

- Show the team the ropes with standard procedures.

- Give standards an occasional makeover.

Sustain

Finally, Sustain is all about sticking to your guns. Keep the 5S principles alive and lively by fostering a culture that’s all about the long haul.

Steps:

- Hit regular check-ins and audits.

- Open the floor for feedback and fresh ideas.

- Bake 5S into the everyday grind.

Nailing down the 5S approach can majorly turbo-charge your workspace mojo. For extra goodies on the kaizen philosophy, don’t forget to browse our sections on kaizen principles and kaizen tools.

Conclusion

Incorporating Kaizen into manufacturing is more than just adopting a set of practices; it’s embracing a mindset of relentless improvement and collective responsibility.

From its humble beginnings in post-war Japan, Kaizen has proven its worth across global giants like Toyota, FedEx Express, and Nike, showcasing its versatility and profound impact on efficiency, waste reduction, and employee satisfaction.

By leveraging core principles such as the PDCA cycle and 5S methodology, companies can foster a culture where every team member contributes to the ongoing enhancement of processes and products.

The success stories highlighted in this article demonstrate that even small, incremental changes can lead to significant, long-term benefits.

As industries continue to evolve, the adaptability and continuous nature of Kaizen make it an invaluable strategy for staying competitive and responsive to market demands. Embracing Kaizen not only drives operational excellence but also cultivates a workplace environment where innovation thrives and employees feel empowered.

Whether you’re looking to streamline operations, reduce costs, or boost morale, Kaizen offers a proven pathway to sustainable growth and enduring success in the manufacturing sector.

FAQs

What is Kaizen in manufacturing?

Kaizen is a Japanese philosophy of continuous improvement that focuses on making small, incremental changes to enhance efficiency, reduce waste, and improve overall productivity in manufacturing processes.

How does the PDCA cycle work in Kaizen?

The PDCA cycle stands for Plan, Do, Check, Act. It is a systematic approach used in Kaizen to identify problems, implement solutions, evaluate results, and make necessary adjustments for continuous improvement.

What are the benefits of implementing Kaizen in manufacturing?

Implementing Kaizen leads to increased efficiency, waste reduction, enhanced employee satisfaction, and a culture of continuous improvement, resulting in higher quality products and lower operational costs.

Can Kaizen be applied to any manufacturing process?

Yes, Kaizen is versatile and can be applied to various manufacturing processes, from small-scale operations to large-scale production lines, by focusing on continuous, incremental improvements tailored to specific needs.

What tools are commonly used in Kaizen?

Common Kaizen tools include the 5S methodology, Value Stream Mapping, Fishbone Diagrams, and Gemba Walks, all of which help identify inefficiencies and streamline processes.

How do companies like Toyota implement Kaizen successfully?

Toyota implements Kaizen through its Toyota Production System (TPS), which emphasizes continuous improvement, waste elimination, and employee involvement, ensuring that every team member contributes to operational excellence.

What is the 5S methodology in Kaizen?

The 5S methodology involves Sort, Set in Order, Shine, Standardize, and Sustain. It aims to create an organized, clean, and efficient workplace that supports continuous improvement and operational excellence.

How does Kaizen enhance employee satisfaction?

Kaizen enhances employee satisfaction by involving all employees in the improvement process, valuing their input, fostering teamwork, and creating a more organized and efficient work environment, which leads to higher morale and job satisfaction.

Final Thoughts

Embracing Kaizen in manufacturing isn’t just a strategy—it’s a cultural shift towards excellence and efficiency. By fostering an environment where every employee is empowered to suggest and implement improvements, companies can achieve remarkable gains in productivity, quality, and employee satisfaction.

The success stories of industry leaders like Toyota, FedEx Express, and Nike serve as powerful testimonials to the transformative power of Kaizen.

As the manufacturing landscape continues to evolve, the principles of continuous improvement, waste reduction, and teamwork will remain essential for businesses striving to stay competitive and innovative.

Whether you’re just starting your Kaizen journey or looking to deepen your implementation, the insights and tools discussed in this article provide a solid foundation for sustained success.

Remember, the path to greatness is paved with small, consistent steps—embrace Kaizen and watch your manufacturing operations thrive.

Main Tips

- Start Small: Implement minor changes first to build momentum and demonstrate the benefits of Kaizen.

- Engage Everyone: Encourage input from all levels of staff to foster a culture of continuous improvement.

- Utilize Kaizen Tools: Leverage tools like the PDCA cycle, 5S methodology, and Value Stream Mapping to identify and address inefficiencies.

- Set Clear Goals: Define achievable objectives to guide your Kaizen initiatives and measure progress.

- Maintain Consistency: Regularly review and sustain improvements to ensure long-term success.

- Provide Training: Educate employees on Kaizen principles and practices to empower them to contribute effectively.

- Celebrate Successes: Acknowledge and reward improvements to motivate ongoing participation and commitment.

Recommended Products and Accessories

- 5S Kits

- Description: Comprehensive kits including labels, color-coded tags, and storage solutions to implement the 5S methodology.

- Example: 5S Workplace Organization Kit

- Value Stream Mapping Software

- Description: Digital tools for creating and analyzing value stream maps to identify and eliminate waste.

- Example: Lucidchart Value Stream Mapping

- Fishbone Diagram Templates

- Description: Printable and digital templates for conducting root cause analysis using Fishbone Diagrams.

- Example: Printable Fishbone Diagram

- Gemba Walk Tools

- Description: Portable devices or notebooks designed for supervisors to use during Gemba Walks for effective observation and note-taking.

- Example: Gemba Walk Notebook

- Kaizen Training Materials

- Description: Books, online courses, and workshops focused on Kaizen principles and implementation strategies.

- Example: Kaizen: The Key To Japan’s Competitive Success by Masaaki Imai

- Lean Manufacturing Books

- Description: Essential literature on Lean and Kaizen methodologies to deepen understanding and application.

- Example: Lean Thinking by James P. Womack and Daniel T. Jones

- Productivity Software

- Description: Tools like Trello or Asana to manage Kaizen projects, track progress, and collaborate with teams.

- Example: Asana Project Management

- Organizational Tools

- Description: Storage solutions, labeling machines, and cleaning supplies to support the 5S methodology and maintain an organized workspace.

- Example: Label Maker Machine

- PDCA Cycle Tools

- Description: Software or physical boards to visualize and manage the PDCA process effectively.

- Example: PDCA Cycle Whiteboard

- Employee Engagement Platforms

- Description: Tools to gather, manage, and implement employee suggestions and feedback, enhancing participation in Kaizen initiatives.

- Example: Officevibe Employee Engagement