In a world where small changes can spark monumental transformations, embracing the Kaizen mindset is your secret weapon for sustained success.

Imagine transforming your daily routines, workplace processes, and personal habits with tiny, continuous tweaks that add up to remarkable improvements over time.

Rooted in Japanese philosophy and perfected by manufacturing giants like Toyota, Kaizen isn’t just a strategy—it’s a way of life fostering innovation, boosting productivity, and cultivating a culture of excellence.

Whether leading a team or striving for personal growth, understanding and implementing Kaizen can pave the way to unparalleled achievements.

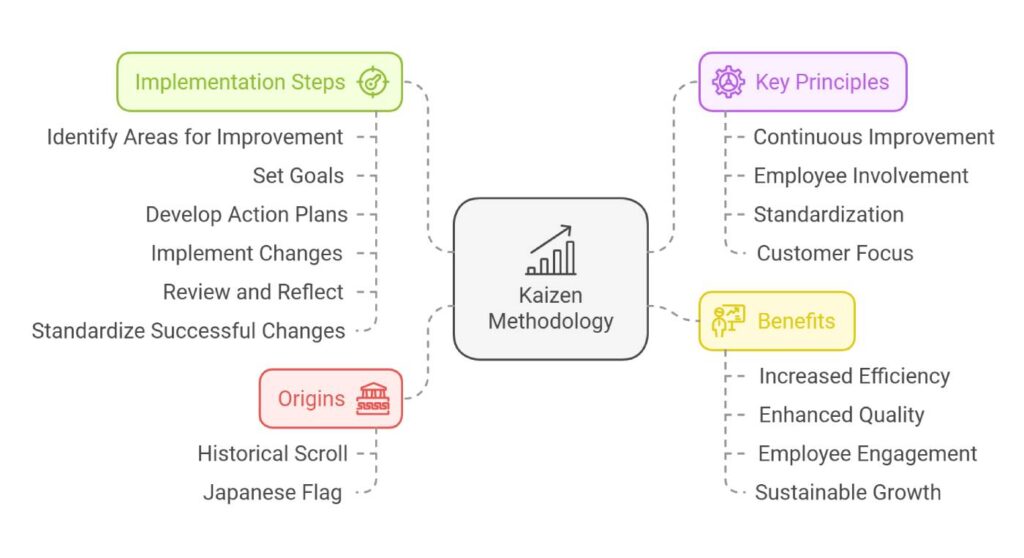

Understanding Kaizen

Origins of Kaizen

So, let’s chat about Kaizen. This term’s got a fancy ring, but it boils down to “change for the better.” Just over three decades ago, Masaaki Imai gave this idea a good push in his book Kaizen: The Key to Japan’s Competitive Success. Picture it a bit like trying to lose weight by ditching the 2 PM snack attack – start small, think big!

After World War II, Kaizen took inspiration from American quality management gurus like W. Edwards Deming. And, oh boy, did it find a snug spot in Japanese manufacturing, especially with Toyota, where they turned it into The Toyota Way.

This wasn’t just a strategy but a movement to mend and boost Japan’s industry bit by bit (ProjectManager).

Evolution of Kaizen Principles

Kaizen didn’t stay in its lane, though. It’s evolved, sneaking out of the factory and into all sorts of places like hospitals, therapy sessions, and even the halls of government offices (Kaizen). At its core, Kaizen is the gospel of making tweaks here and there with everyone jumping in – from the janitor to the CEO.

What Kaizen Preaches:

- Make those little adjustments regularly.

- Don’t just do stuff for the sake of it; cut out useless bits.

- Get everyone, and I mean everyone, involved, so it feels like a team thing rather than just another office drill sergeant barking orders.

Kaizen’s Impact:

- Cranks up productivity.

- Foster’s new ideas.

- It gets everyone accountable and on board.

| Principle | Description |

|---|---|

| Incremental Changes | Small, regular improvements |

| Elimination of Waste | Removing inefficiencies in processes |

| Collective Responsibility | Involving everyone in continuous improvement |

Fast forward to today, and Kaizen isn’t just some old-school thing. Companies from Toyota to up-and-coming startups swear by it (TechTarget). It’s not just for work, either. Folks use Kaizen vibes in personal life hacks too, like spicing up your everyday routines or even saving up for that dream vacation (Spica).

If you wanna know more about Kaizen magic, our deep dive into continuous improvement kaizen and kaizen methodology won’t disappoint. Dive in and see how these small changes can eventually lead to big wins!

Fundamental Principles of Kaizen

Successful organizations don’t just fall from the sky. They’re built brick by brick with a sprinkle of the Kaizen approach—a philosophy that thrives on tiny, steady tweaks that lead to big wins. For anyone holding the reins of a business, knowing your way around the basics of Kaizen can turn the ordinary into the extraordinary.

Guiding Principles of Kaizen

Years back, a guy named Masaaki Imai gave the world a game-changer with his book “Kaizen: The Key to Japan’s Competitive Success”. He laid out a plan that’s simple but pure gold. Here’s what you need to know about making ‘better’ your best friend:

- Customer Focus: Your clientele is the hero of your story. Keep their needs front and center.

- Total Quality Control: Excellence should flow through every nook and cranny of your process.

- Teamwork: Think of everyone on the team as bandmates making the same sweet music.

- Personal Discipline: Encourage folks to put their heart into the game and take ownership of their work.

- Suggestion System: Give everyone a voice; you never know where the next big idea will pop up.

These principles are your best pals in creating that culture of “let’s do it better, a bit at a time.” For a detailed rundown, hit up our article on kaizen principles.

Role of Kaizen in Continuous Improvement

With Kaizen, you’ve got a recipe for constant upgrades, one spoonful at a time, keeping things fresh and flexible. Here’s what a dash of Kaizen magic can do for you:

- Lower Defects: Keeping an eye on things like a hawk and making tweaks stops those pesky mistakes.

- Eliminate Waste: Ditch the stuff dragging you down, making your way of working smoother.

- Boost Productivity: Little by little, your team ramps up and nails efficiency.

- Worker Purpose and Accountability: When folks are involved in the action, they find meaning and a reason to step up.

Understanding Kaizen is all about embracing its ‘wash, rinse, repeat’ nature. It’s about staying sharp, listening, and adapting when the winds change. For the whole scoop on how Kaizen can work wonders for your biz, hop over to our Kaizen methodology.

| Area of Improvement | How It Pays Off |

|---|---|

| Defect Reduction | Better products |

| Waste Elimination | Cheaper operations |

| Productivity Boost | More work, less hassle |

| Employee Engagement | Sky-high morale and ownership |

To really rev up that improvement engine, you need to get cozy with systematizing processes and strike the perfect balance between local wins and big-picture goals. With this balanced approach, improvements come like a waterfall—steady, nourishing, and cleansing.

By soaking up that kaizen culture, businesses can morph dramatically. It all kicks off with grasping and applying these guiding principles and seeing Kaizen’s role as the secret sauce in continuous improvement. For a treasure chest of strategies, dive into our guide on kaizen strategies.

Implementing Kaizen Methodology

Getting the Kaizen ball rolling isn’t as tough as you might think, but it does need a bit of structure. Here’s a fun look at how a solid game plan and a healthy dose of teamwork make all the difference in keeping the wheels of improvement turning smoothly.

Kaizen Action Plan

Having a go-to game plan is key to weaving Kaizen principles into the fabric of any organization. It’s kinda like getting everyone on the same page and making sure no one’s left out of the loop.

- Define Objectives: Clearly lay out what needs doing, ensuring everyone’s pulling in the same direction.

- Identify Areas of Improvement: Tools like Root Cause Analysis and Total Quality Management step into spotlight areas begging for attention.

- Develop a Plan: Whip up a game plan for tackling the issues with the PDCA Cycle — Plan, Do, Check, Act.

- Implement Solutions: Start small. Tiny tweaks can lead to big shifts. Get everyone’s brains in gear for input.

- Evaluate and Adjust: Keep a keen eye on the results to tweak things to keep on improving.

Rolling with the Kaizen plan means team collaboration is front and center. Giving folks the freedom to step up fosters a vibe of constant idea-sharing ProjectManager.

| Stage | Description |

|---|---|

| Plan | Define Objectives, Spot Improvements |

| Do | Implement those neat solutions, Get folks involved |

| Check | Look back at results, Gather feedback vibes |

| Act | Fix what flops, Amp up those winning improvements |

Importance of Team Collaboration

Working as a team isn’t just important, it’s like the secret sauce of making Kaizen methodology a real winner. A cozy team setting means ideas bounce around faster than a pinball.

- Valuing Employee Input: Every voice counts in Kaizen-land. Folks on the front line often have the best insights.

- Autonomy for Action: Freedom to act on bright ideas gives a real sense of ownership and makes everyone a part of the improvement journey.

- Trust and Engagement: Teams thrive on trust. It leads to open chats and the courage to try new things.

- Continuous Improvement Mindset: Bite-sized changes conquer big challenges, flipping problems into growth ops.

Sprinkle in kaizen training and kaizen workshops to turbocharge your team’s Kaizen know-how and ensure everyone understands what’s what. For more chitchat on building a team spirit around Kaizen, dive into our Kaizen culture.

By building a rock-solid Kaizen plan and encouraging team camaraderie, organizations can tap into the true spirit of Kaizen, endlessly leveling up across the board.

Kaizen Methodology

Kaizen isn’t just another buzzword—it’s a mindset focused on sneaky small changes that stack up over time. Imagine a more chill version of lean manufacturing, where everyone in the office—yes, even Bob from accounting—plays a part in cutting down on waste and shaking things up a little. So, let’s see how Kaizen gets its groove on by zeroing in on those tiny wins and how they snowball into continuous improvement.

Emphasizing Small Improvements

Kaizen is all about believing in the power of baby steps. Think of it like this: small tweaks here and there can lead to huge payoffs down the road. So, everyone pitches in with their two cents on making their everyday tasks a tad bit smoother. When you add up all these little gems of wisdom, the results are pretty impressive.

Here’s what small improvements tackle:

- Cutting down on waste

- Trimming defects

- Pumping up productivity

- Boosting employee buy-in

- Lighting up innovation

These little victories mean a lot more than just happier customers—they push the quality of your products or services up a notch.

| Aspect | Benefit |

|---|---|

| Waste Reduction | Lower bills to pay on payday |

| Defect Cutting | Better stuff to sell |

| Productivity Boost | Work-life made easy |

| Worker Buy-In | More people who actually care |

| Innovation | Shiny new ideas galore |

If you’re looking for more tips on tweaking things the Kaizen way, check out our Kaizen process improvement guide.

Continuous Improvement Iterations

Kaizen loves to keep things moving with baby-step changes rather than blowing everything up for a reboot. This focus on little improvements here and there keeps the ball rolling and ensures progress doesn’t just fizzle out eventually (BeeWaTec).

Here are some nifty Kaizen tricks for keeping the juices of continuous improvement flowing:

- PDCA Cycle (Plan-Do-Check-Act): A loop of change—plan it, do it, check it, fix it.

- 5S Method: Keep your workspace neat and tidy.

- Kaizen Workshops: Let’s solve some problems as a team, folks!

- Gemba Walks: Management strolls around to figure out what’s really going on.

- Kanban: Visual board games for tracking how stuff moves around.

- Quality Groups: Team pow-wows focused on perfecting things.

- Standard Operating Procedures: Setting the gold standard with the best playbook.

- Value Stream Mapping: Untangling the flow of info and materials like a pro.

These handy methods, whether they stand alone or buddy up, make improvements to every nook and cranny of an organization. For more on keeping the momentum going, check out our write-up on continuous improvement kaizen.

Empowering Kaizen to do its magic hinges on everyone’s commitment to these small shifts and embracing the Kaizen vibe wholeheartedly. This dedication to tweaks and refinements breathes life into a kaizen culture, syncing your day-to-day with the core ideals of ongoing betterment.

Kaizen Mindset

Defining the Kaizen Attitude

The “Kaizen attitude” is like the friendly nudge that keeps pushing an organization forward. It’s a vibe that hums through every office, warehouse, and Zoom call, asking everyone, even the big cheeses, to not just sit tight but to roll up their sleeves and tackle hiccups head-on, rather than just chatting about why they’re a pain.

This attitude boils down to:

- Determination: A never-ending hunger to make everything better.

- Team Spirit: The kind of camaraderie where y’all paddle the same boat with trust and sincerity.

- Fix It Like You Mean It: Be soft on people but hard on issues, always tinkering and trying ideas on for size rather than waiting for the star solution.

- Keep On Growing: Much like Carol Dweck talked about in her study on growth mindsets, Kaizen carries a belief in moving forward through grit and smarts.

With this Kaizen vibe, a workplace turns into a zone where everyone’s got a seat at the table when it comes to making things better (kaizen principles).

Differentiating Kaizen from Kaikaku

Getting what makes Kaizen tick as opposed to Kaikaku is key if you’re in the biz of constant betterment.

| Aspect | Kaizen | Kaikaku |

|---|---|---|

| Definition | Little steps of never-ending tinkering | Big, game-changing shifts |

| Approach | Bit by bit | In-your-face transformation |

| Change Frequency | Non-stop, like clockwork | Once in a blue moon |

| Impact | Builds over time | Packs a punch fast |

| Example | Tweaking the production line little by little | Gutting and revamping manufacturing from the ground up |

What Sets Kaizen Apart

Kaizen is all about those tiny steps that add up. Imagine giving your workspace little nudges for better flow, nudging productivity up a notch, or fixing minor knicks in efficiency (kaizen methodology). Keep at it, and these small moves bring about considerable long-term goodness without the big splash that comes with colossal changes.

Kaikaku: Radical Change

Kaikaku is a different beast, ushering in sweeping, groundbreaking shifts that shake things up in a company. It’s not for the faint-hearted, packing speed and punch, but less often than Kaizen. While Kaikaku can flip the board for solid wins fast, it calls for serious forethought, plenty of resources, and knowing your ducks are lined for the changes to stick and not hit like a ton of bricks.

To get a hang of when and how to mix these styles, don’t miss our pieces on kaizen process improvement and kaizen methodology.

Seeing the pros in both Kaizen and Kaikaku, and knowing when to pull out each card lets businesses take steady steps and big jumps, nurturing progress and flexibility in an ever-hustling biz scene.

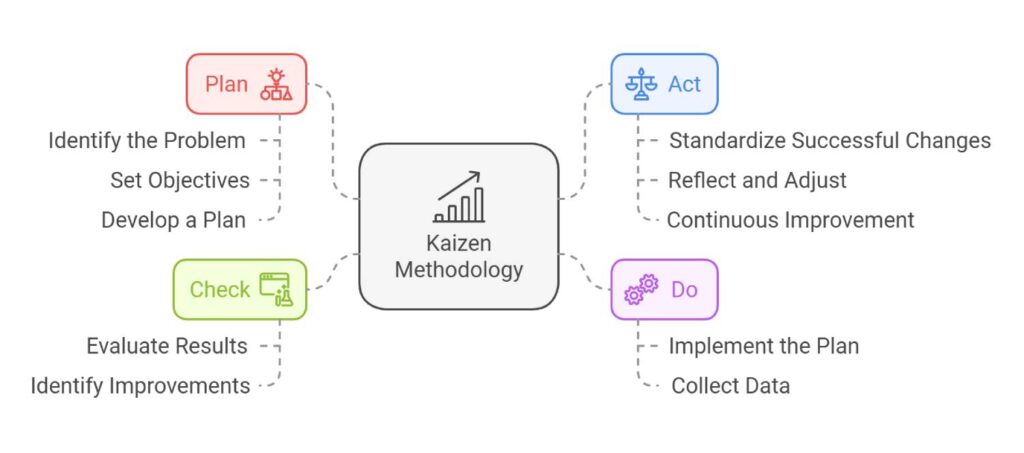

PDCA Cycle in Kaizen

The PDCA Cycle, or the Deming Cycle as some folks might call it, is like the engine that keeps Kaizen rolling along smoothly, pushing for betterment one step at a time. This journey is broken down into four parts: Plan, Do, Check, and Act. Getting a good handle on these parts can really boost a company’s kaizen process improvement game.

Plan Stage

Let’s kick things off with the Plan stage, where you set your sights on what you want to achieve. It’s like drawing up a game plan. Teams get together to spot problems, dig deep into what causes them, and lay out how they’re gonna fix it all up. The ‘5 Whys Analysis,’ for instance, is handy for cracking tough nuts. During this brainstorming bonanza, teams sketch out who does what, when it all happens, and what the grand finale should look like.

Do Stage

Now onto the Do stage—time to roll up your sleeves. Here, we take the plan from earlier and give it a whirl with a small-scale test run. It’s like dipping your toe in before diving in. Keeping a close eye here is key to making sure everything’s on track and not going off the rails.

Check Stage

Next stop, the Check stage. This is where you pull in the results and see if what you did actually worked. Data gets gathered, performances get scrutinized, and you see if your little experiment brought the goodies you were aiming for. Did things go as planned, or are there some tweaks needed? It’s data-crunching time!

| Stage | Key Activities | Tools |

|---|---|---|

| Plan | Sniff out issues, aim high, draft a game plan | 5 Whys Analysis, Root Cause Analysis |

| Do | Get things going on a small scale, keep tabs | Action Plans, Checklists |

| Check | See how you did, crunch numbers, spot the gaps | Metrics, Performance Indicators |

| Act | Lock in wins, tweak where needed | Standard Operating Procedures (SOPs), Continuous Eyeballs |

Act Stage

Finally, the Act stage, where we take what’s working and spread it out company-wide. If the strategy isn’t quite there yet, it’s back to the drawing board for some fine-tuning, and we start this adventure anew. This rinse and repeat method fuels consistent tuning and elevating, nurturing a strong kaizen culture in the biz.

Taking the PDCA cycle under your wing as part of the kaizen mindset helps businesses churn out continuous improvement, smoothens processes, and sparks a lively atmosphere of innovation. Want to dig deeper? Check out more on kaizen methodology and how it can drive success stories across the board.

Systemization for Continuous Improvement

Bringing continuous improvement into a company means getting it done with a solid plan to fix problems and make things better on both small and big scales.

Problem-Solving Process

Having a good problem-solving process is key to rocking that kaizen mindset. It’s all about using tried-and-true ways to dig out the real issues, throw some solutions at them, and make sure improvements stick around.

The big wig here is the PDCA Cycle (Plan, Do, Check, Act), cooked up by William Edwards Deming. This cycle is a staple of the kaizen methodology and is a go-to in quality control, lean management, and running projects.

| Problem-Solving Stages | Description |

|---|---|

| Plan | Spot problems and outline goals |

| Do | Implement changes and get the ball rolling |

| Check | See if it worked and crunch the numbers |

| Act | Get on those fixes for ongoing improvement |

Throwing in extras like Kaizen workshops, Gemba walks, and Quality groups brings more muscle to solving problems. These get everyone involved and keep learning on the go, laying the groundwork for lasting benefits.

Balancing Local and Global Optimization

When going for Kaizen, nailing that balance between tweaking small parts (local optimization) and the whole shebang (global optimization) is a big deal. It’s a tango between fine-tuning specific bits and keeping an eye on the whole operation so both get better.

| Optimization Level | Key Focus Areas | Potential Benefits |

|---|---|---|

| Local Optimization | Specific departments, individual processes | Doing more with less, cutting out waste |

| Global Optimization | Overall performance, cross-departmental processes | Happier customers, long-term success |

Using things like the 5S method and Value Stream Mapping really helps juggle local and global tweaks. The 5S method is all about making the place run smoother, giving Kaizen a strong starting point. Value Stream Mapping helps spot waste and inefficiencies, letting companies cut through the clutter for peak performance.

For more in-depth tips, swing by our pieces on kaizen strategies and kaizen systemization.

By bringing these tactics, tools, and strategies on board, companies can really push that culture of constant betterment, boosting improvements both locally and globally in how they operate.

Kaizen Culture in Organizations

Jumping on board with the Kaizen mindset can shake things up in a big way for any organization. Always reaching for improvement and teamwork, sets the stage for big changes. Let’s break down some important pieces of building this Kaizen culture: trusting and working with others and making choices based on solid evidence.

Building Trust and Collaboration

At the heart of Kaizen is getting everyone, from the big bosses to the newbies, to keep tinkering with how things are done and find better ways. This “Kaizen attitude” isn’t just about feeling stuck; it’s about working together to move forward and truly trusting each other to get there.

- Trust: It’s not some mysterious quality; trust happens when folks are encouraged to pitch ideas and jump into solving issues. When people know they’re valued and can speak up, magic happens.

- Collaboration: You get the best ideas when everyone bounces off each other. And doing it right means having regular get-togethers, whether it’s meetings, workshops, or just feedback sessions to hear each other out.

- Intelligent Risk-Taking: Kaizen is all about taking smart risks. It’s spotting the big issues, and then using tools like the Impact Effort Matrix to decide where to focus your energy.

Creating a spot where trust and teamwork can thrive means the whole team can give it their all, steering the ship toward never-ending improvement.

Data-Driven Decision-Making

Making decisions based on a gut feeling? Not in Kaizen. Here, it’s all about the data. Every choice or guess needs to have proof behind it. Use tools like the PDCA Cycle (Plan, Do, Check, Act), Hoshin Kanri, Total Quality Management, and Root Cause Analysis to back it all up.

| Tool | Description |

|---|---|

| PDCA Cycle | A keep-on-learning loop that helps with planning, doing, checking, and acting for ongoing betterment. |

| Hoshin Kanri | A clever way of making sure everyone is working toward the same big goals. |

| Total Quality Management (TQM) | A whole-company way to make sure everything’s running smoother and better every day. |

| Root Cause Analysis (RCA) | A detective-like method to get to the bottom of a problem. |

When decisions are driven by data, it’s about these ideas:

- Evidence-Based Decisions: Decisions are smart if they’re grounded in facts, not assumptions, making actions more sensible.

- Problem Identification: Use tools like Root Cause Analysis to really get to the root of what’s bugging you.

- Performance Monitoring: Keep an eye on how things are going with key performance indicators (KPIs) to find where you can do better.

With the Kaizen mindset, it’s always about moving forward with your eyes open, backed by data you can trust. Want more tips on putting these ideas into practice? Check out our article on Kaizen process improvement.

By melding trust, teamwork, and decisions based on data, organizations can build a solid Kaizen culture. This kind of environment encourages endless learning and keeps a business on its toes, paving the way for long-term success. Get into how Kaizen can work for your business with Kaizen in business.

Conclusion

As we’ve journeyed through the transformative power of the Kaizen mindset, it’s clear that embracing continuous, incremental improvements can revolutionize both organizations and personal lives.

From its humble beginnings in post-war Japan, inspired by quality management pioneers like Deming, Kaizen has evolved into a universal philosophy that champions small, consistent changes over grand, disruptive overhauls.

Whether you’re streamlining processes in a bustling factory, enhancing team collaboration in an office, or refining your daily habits at home, Kaizen provides a framework for sustainable growth and excellence.

By focusing on eliminating waste, fostering collective responsibility, and nurturing a culture of trust and data-driven decision-making, Kaizen not only boosts productivity and innovation but also empowers every individual to contribute meaningfully to the greater goal.

Remember, it’s the little things that often make the biggest difference. So, start today with small steps, involve your team, and watch as these tiny tweaks lead to monumental successes.

Embrace the Kaizen mindset and unlock your path to lasting improvement and unparalleled success.

FAQs

What is the Kaizen mindset?

Kaizen is a Japanese philosophy focused on continuous, incremental improvement in all aspects of life and business.

How does Kaizen improve productivity?

By implementing small, consistent changes, Kaizen eliminates waste and optimizes processes, leading to increased efficiency and productivity.

What are the key principles of Kaizen?

The key principles include incremental changes, elimination of waste, collective responsibility, teamwork, and data-driven decision-making.

How can Kaizen be applied in personal life?

Kaizen can be applied by making small, daily improvements in routines, habits, and personal goals to achieve long-term growth and success.

What is the difference between Kaizen and Kaikaku?

Kaizen focuses on continuous, small-scale improvements, while Kaikaku involves radical, large-scale changes for quick transformation.

Final Thoughts

Embracing the Kaizen mindset is more than just adopting a set of practices—it’s about cultivating a culture of continuous improvement and collective responsibility.

By making small, consistent changes, organizations and individuals can achieve significant, long-lasting success. Whether you’re striving to enhance workplace efficiency, foster innovation, or pursue personal growth, the principles of Kaizen offer a clear and effective pathway.

Remember, it’s the cumulative impact of these incremental steps that leads to remarkable transformations. Start today by identifying one small area to improve, involve your team, and watch as the Kaizen philosophy drives your journey toward excellence.

Main Tips

- Start Small: Begin with minor changes that can be easily implemented and gradually build upon them.

- Involve Everyone: Engage all team members, from top management to frontline workers, to foster a collaborative improvement culture.

- Eliminate Waste: Regularly identify and remove inefficiencies in your processes to enhance productivity.

- Use Data-Driven Decisions: Base your improvements on solid data and analysis to ensure effectiveness.

- Foster a Continuous Improvement Mindset: Encourage ongoing learning and adaptation to sustain long-term growth.

- Implement the PDCA Cycle: Utilize the Plan-Do-Check-Act framework to systematically approach improvements.

Recommended Products and Accessories

- Kanban Boards: Visual management tools like Trello or Asana to track tasks and improvements.

- 5S Toolkit: Organizational tools including labels, storage bins, and cleaning supplies to implement the 5S method.

- PDCA Cycle Software: Applications such as the Plan-Do-Check-Act (PDCA) Cycle Tool for managing improvement cycles.

- Root Cause Analysis Templates: Digital templates from Lucidchart for conducting root cause analysis.

- Continuous Improvement Books: Essential reads like “Kaizen: The Key to Japan’s Competitive Success” by Masaaki Imai.

- Team Collaboration Tools: Platforms like Slack or Microsoft Teams to facilitate communication and idea sharing.

- Gemba Walks Checklist: Printable or digital checklists to guide management during Gemba walks.

- Kaizen Workshops Kits: Materials for conducting Kaizen workshops, including flip charts, markers, and brainstorming supplies.